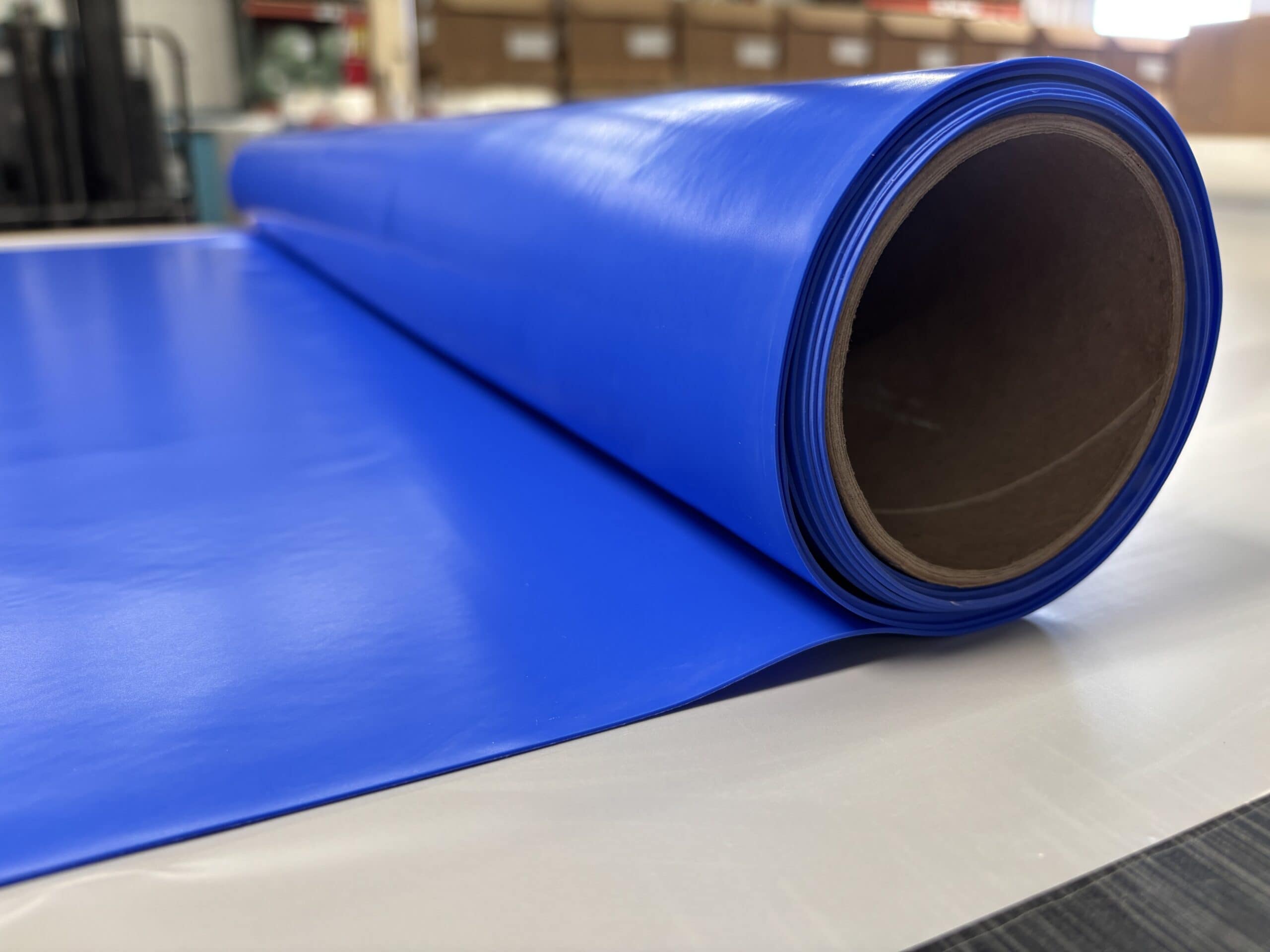

ElastaPro makes fluorosilicone rubber at our Made in USA manufacturing facility in Santa Fe Springs, California. Domestic sourcing can help you to reduce supply chain risk, but that’s not the only reason to buy high-performance materials from us. ElastaPro manufactures fluorosilicone rubber as solid sheets and uncured compound in accordance with our ISO 9001:2015 and AS9100D certified quality management system. Moreover, we offer a full Certificate of Analysis (COA) with each batch.

Why Choose Domestic Fluorosilicone Rubber?

Domestic sourcing reduces your supply chain risk by shortening shipping distances, minimizing transportation touchpoints, and allowing for quicker responses to disruptions such as geopolitical disputes, natural disasters, and pandemics. Along with shorter lead times and greater visibility, the benefits include reduced exposure to international trade issues such as tariffs, border closings, and shipping delays. It’s also easier to coordinate and collaborate with a Made in USA manufacturer.

Even if you can’t visit us in California to meet face-to-face, ElastaPro makes communications easy. Whether you pick up the phone, send us an email, or use the chatbot or contact form on our website, we pride ourselves on quick and responsive service. We’re also available for Teams or Zoom calls and regularly update our website with technical content and descriptions. For example, the fluorosilicone page on our website let you download technical data sheets.

Why Ask for a Fluorosilicone COA?

A Certificate of Analysis (COA) is a document that provides the test results for a specific batch of a material. By contrast, a Certificate of Conformance (COC) simply attests that a material meets requirements. In other words, a COC does not provide batch-level test data. That’s a key distinction in industries like aerospace and defense, both of which use fluorosilicone rubber because of its wide temperature range, superior resistance to fuels and solvents, and ability to meet standards.

ElastaPro provides a full COA with each batch and includes key specifications such as tensile strength, elongation, compression set, hardness, and temperature range testing. Importantly, our COAs demonstrate that our flurosilicone rubber complies with standards such as AMSR-25988, which was published by SAE International and supersedes MIL-DTL-25988. Older prints may still reference MIL-R-25988, which is sometimes written as MILR-25988 instead.

What If There’s a Spec Change or Substitution?

Fluorosilicone specs are subject to change, and suppliers sometimes change the ingredients in their products. That’s why ElastaPro performs a full qualification whenever there’s a spec change or we update a raw material. We also conduct full lot-to-lot verification in accordance with the spec, which contains a table for testing during lot-to-lot qualification work. In the AMSR-25988 specification, Table IV outlines material property requirements.

Ask ElastaPro for Flurosilicone Rubber

Do you need spec-grade fluorosilicone rubber with a full COA for traceability? Have you considered how partnering with a Made in USA materials manufacturer can help you to reduce supply chain uncertainty while ensuring quality? For fluorosilicone solid sheet and uncured compound, the name you can trust is ElastaPro. Contact us for proven materials you can depend upon.