Extreme Low Temperature Silicone

Extreme low temperature silicone from ElastaPro is designed for low temperature applications in aerospace, defense, and cryogenics. It’s excellent for seals and gaskets, provides UV and ozone resistance, and is an excellent electrical insulator. This made-to-order material is available in solid silicone sheet in many colors and comes in thicknesses from .010” to .500” and widths up to 60”. Uncured silicone compound is also available.

Note: ElastaPro also makes an extreme low temperature silicone with high strength.

30 to 80 Durometer Extreme Low Temperature Silicone

Extreme low temperature silicone comes in the following durometers.

- ESS30LT – 30 Durometer Extreme Low Temperature

- ESS40LT – 40 Durometer Extreme Low Temperature

- ESS50LT – 50 Durometer Extreme Low Temperature

- ESS60LT – 60 Durometer Extreme Low Temperature

- ESS70LT – 70 Durometer Extreme Low Temperature

- ESS80LT – 80 Durometer Extreme Low Temperature

Key Characteristics

- Extreme High & Low-Temperature Resistant -130ºF to +450ºF (525ºF Intermittent)

- Excellent for Seals & Gaskets

- Fabricated with high-quality raw materials

- UV / Ozone Resistant & Excellent Electrical Insulator

- SPECIFICATIONS: AA-59588 CL1A/1B, AMS 3334, 3335, 3336, 3337, 3338

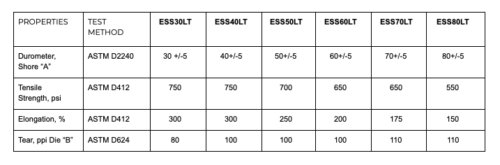

Material Properties

The table below shows material properties for ElastaPro’s extreme low temperature silicone.

What is Extreme Low Temperature Silicone?

Extreme low temperature silicone is a specialized grade of silicone rubber that remains flexible, elastic, and functional at temperatures far below the range of standard silicones. While general-purpose silicone typically performs well down to about -60°C (-76°F), extreme low temperature silicone can remain stable and pliable at temperatures as low as -100°C (-148°F) or lower, depending on the formulation.

Advantages

- Superior Flexibility in Cold: It doesn’t become brittle or crack in cryogenic or arctic conditions.

- Thermal Stability: Operates across a wide temperature range — often from -100°C to +200°C.

- Durability: Maintains its mechanical properties (tensile strength, elongation) in extreme environments.

- Resistance to Environmental Stress: Withstands UV, ozone, and weathering, even in sub-zero conditions.

- Chemically Inert: Compatible with many chemicals used in aerospace, medical, and cryogenic applications.

Applications

-

Aerospace and aviation (high altitude, unheated environments)

-

Cryogenic systems (storage tanks, transfer lines)

-

Arctic oil and gas operations

-

Military and defense electronics

-

Medical freezers and cold chain logistics

How It’s Different from Standard Silicone:

| Property | Standard Silicone | Extreme Low Temp Silicone |

|---|---|---|

| Low Temp Limit | ~ -60°C (-76°F) | ~ -100°C (-148°F) or lower |

| Elasticity at Cold | Becomes less flexible | Remains pliable and soft |

| Formulation | General PDMS base | Modified PDMS or fluorosilicone |

| Typical Uses | Seals, gaskets, tubing | Aerospace, deep-sea, cryogenics |

| Cost | Less expensive | More costly due to specialty |