-

FDA Silicone: The Gold Standard in Health and Safety Compliance

FDA silicone refers to products that comply with the regulations set forth by the United States Food and Drug Administration (FDA). These regulations govern the safe use of silicone-based items in medical, pharmaceutical, food, and beverage applications. They also guarantee that the materials are non-toxic, chemically inert, and do not impart harmful substances into the products.

This article will explore the importance of FDA-approved silicone in various industries and the specific regulations and standards it must meet.

Significance of FDA Silicone Across Industries

FDA-approved silicone is pivotal across various industries due to its exceptional properties and adherence to stringent regulatory standards. In the food and beverage industry, this material is important to ensure the safety and quality of products. Its non-toxic nature prevents contamination and maintains the integrity of various food items, from processing equipment to packaging materials.

Using FDA silicone is also imperative in the pharmaceutical and medical sectors to uphold patient safety and regulatory compliance. Its exceptional biocompatibility, sterility, and resistance to chemical degradation make it indispensable in implants, catheters, and tubing. They are designed to be in direct contact with the human body for prolonged periods.

Furthermore, FDA silicone finds applications in various consumer products, from personal care items to industrial machinery. Its versatility and safety profile make it preferable for goods like baby bottle tubes, kitchen utensils, and automotive components. Manufacturers can instill consumer confidence regarding product safety by selecting this material for such applications.

FDA Regulations and Standards for Silicone Products

Compliance with the following regulations and standards is essential for silicone product manufacturers to ensure safety, effectiveness, and regulatory approval:

21 CFR Part 177

This regulation outlines the requirements for polymers including silicone intended for use in contact with food. It specifies permissible additives, maximum extractable levels, and overall safety criteria to prevent the migration of harmful substances into food.

USP Class VI

The United States Pharmacopeia (USP) Class VI standard applies to materials used in medical and pharmaceutical devices. Silicone products must meet cytotoxicity, sensitization, and systemic toxicity assessments to ensure they are safe for medical use.

ISO 10993

This international standard provides guidelines for evaluating the biological safety of medical devices, including silicone-based components. It encompasses various tests such as irritation, genotoxicity, and implantation tests to assess the compatibility of silicone materials with the human body.

ISO 9001 and ISO 13485

While not specific to silicone products, these quality management standards are relevant for producers of medical devices and pharmaceutical products incorporating silicone. Compliance with ISO 9001 ensures consistent quality control processes, whereas ISO 13485 focuses on meeting regulatory requirements for medical device manufacturing.

ISO 14971

This standard specifies requirements for risk management of medical devices, including those containing silicone. It entails identifying and mitigating hazards associated with silicone components, ensuring that risks are minimized.

FDA 510(k) Clearance

This process evaluates the safety and effectiveness of new medical devices compared to existing products. It ensures that silicone components meet regulatory requirements before being marketed in the United States.

FDA Master Files

Manufacturers may submit Master Files to the FDA containing confidential information about silicone materials’ safety, composition, and processing. These documents can streamline the regulatory review process for companies utilizing silicone product components.

Partner With ElastaPro Silicone Sheeting for Your Silicone Needs

At ElastaPro Silicone Sheeting, we offer high-quality silicone products and services tailored to meet global clients’ diverse needs! Our extensive portfolio spans industries including healthcare, automotive, electronics, and beyond catering to a wide array of applications and requirements. We also adhere to stringent quality control measures throughout our manufacturing process.

Contact us today to learn more about our solutions!

-

Calendered Silicone: The Process, Benefits, and Its Multitude of Uses

There are three primary methods to fabric silicone rubber products; molding, extrusion and calendering. Calendering plays a pivotal role in creating high-quality silicone products for gaskets, seals, o-rings and a variety of other products with various geometries and configurations. This manufacturing process involves passing raw silicone through a series of rollers under high pressure with a specific gap to establish the thickness of the sheet. The result is a silicone sheet with uniform thickness and smooth surface finish, suitable for various applications.

This blog will delve into the intricacies of calendered silicone, from its production process to its many applications.

The Process of Calendering Silicone

The process begins with raw silicone polymer, typically in the form of a gum or compound where additional ingredients are added to the material to meet key specifications . The silicone is performed for loading into the calendar.

Next, the silicone is fed into a calendering machine, where it passes through multiple rollers to control the thickness and surface characteristics of the silicone. Once the calendering process is complete, the silicone sheet may undergo a curing and post cure process or be supplied to fabricators in an uncured format. Cured silicone sheet may receive further treatment such as Pressure Sensitive Adhesive Application and slitting or cutting into specific dimensions based on customer requirements.

Quality control measures are implemented throughout the calendering process to monitor thickness, surface finish, and other relevant parameters. This ensures that the resulting silicone sheets meet the required specifications and quality standards. The silicone sheets are then packaged and prepared for distribution.

Benefits of Calendered Silicone

Here are some of the advantages of this silicone material:

- Flexible: Calendered silicone can bend, stretch, and adapt to various shapes without losing its integrity.

- Temperature-resilient: This silicone material maintains its properties across a wide temperature range from extreme cold to high heat making it suitable for diverse environments.

- Chemical-resistant: Calendered silicone exhibits resistance to various chemicals, oils, and solvents. This is why it is often used in applications where exposure to these substances is common.

- Weatherproof: Resisting weathering and UV radiation makes this silicone ideal for outdoor applications. It can endure exposure to sunlight and weather conditions without significant degradation.

- Biocompatible: This type of silicone is well-tolerated by the human body, making it suitable for various applications in the medical field.

- Customizable: Manufacturers can tailor calendered silicone sheets to meet specific requirements. This enhances its applicability in various industries and niche applications.

Versatile Uses of Calendered Silicone

Thanks to its unique properties and benefits, calendered silicone finds diverse applications across various industries:

- Automotive seals and gaskets: This type of silicone is ideal for seals and gaskets in vehicle components due to its resistance to heat and chemicals, or for thermal management in Electric Vehicles.

- Electrical insulation: Thanks to its excellent dielectric properties, calendered silicone insulates wires, cables, and electronic components.

- Flexible printed circuit boards (PCBs): This material can be used for flexible PCBs for electronic devices, allowing for versatile and bendable electronic components.

- Medical devices: Calendered silicone is utilized in medical equipment and devices for its biocompatibility, flexibility, and resistance to sterilization methods.

- Solar panel encapsulation: This silicone material is commonly applied in the encapsulation of solar panels to protect them from environmental factors and enhance their durability.

- Textile coating:Calendered silicone can be applied as a coating on textiles to make them resistant to water, heat, and chemicals.

- Weatherstripping: This material is typically used to manufacture weather stripping for doors and windows, providing insulation and protection against the elements.

ElastaPro: Your First Choice in Silicone Sheet Solutions

ElastaPro Silicone Sheeting is your go-to source for premium silicone products! Our company is founded by seasoned veterans in the silicone industry. Moreover, we boast decades of experience, high precision equipment, and proprietary manufacturing techniques. We offer US-made, high-quality products from calendered silicone sheets to uncured silicone compounds in standard and customized options.

Contact us today to explore our premium solutions!

-

A Deep Dive Into AA 59588: Standards, Compliance, and Industry Implications

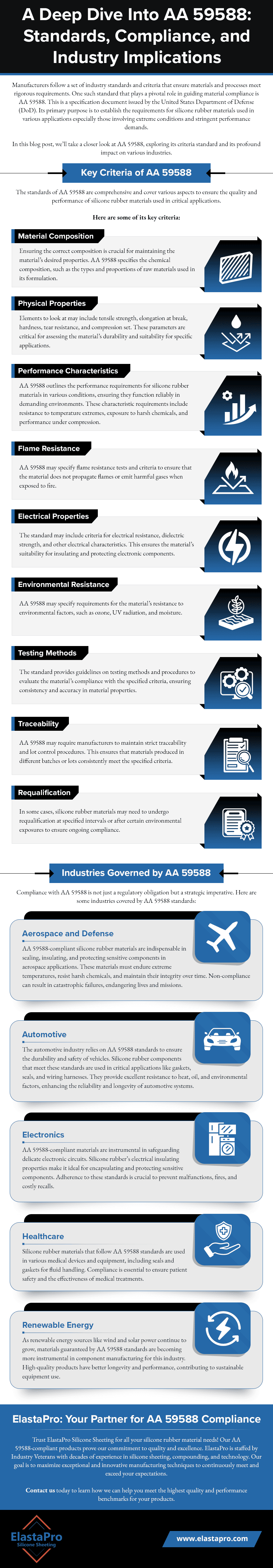

Manufacturers follow a set of industry standards and criteria that ensure materials and processes meet rigorous requirements. One such standard that plays a pivotal role in guiding material compliance is AA 59588. This is a specification document issued by the United States Department of Defense (DoD). Its primary purpose is to establish the requirements for silicone rubber materials used in various applications especially those involving extreme conditions and stringent performance demands.

In this blog post, we’ll take a closer look at AA 59588, exploring its criteria standard and its profound impact on various industries.

Key Criteria of AA 59588

The standards of AA 59588 are comprehensive and cover various aspects to ensure the quality and performance of silicone rubber materials used in critical applications. Here are some of its key criteria:

- Material composition: Ensuring the correct composition is crucial for maintaining the material’s desired properties. AA 59588 specifies the chemical composition, such as the types and proportions of raw materials used in its formulation.

- Physical properties: Elements to look at may include tensile strength, elongation at break, hardness, tear resistance, and compression set. These parameters are critical for assessing the material’s durability and suitability for specific applications.

- Performance characteristics: AA 59588 outlines the performance requirements for silicone rubber materials in various conditions, ensuring they function reliably in demanding environments. These characteristic requirements include resistance to temperature extremes, exposure to harsh chemicals, and performance under compression.

- Flame resistance: AA 59588 may specify flame resistance tests and criteria to ensure that the material does not propagate flames or emit harmful gases when exposed to fire.

- Electrical properties: The standard may include criteria for electrical resistance, dielectric strength, and other electrical characteristics. This ensures the material’s suitability for insulating and protecting electronic components.

- Environmental resistance: AA 59588 may specify requirements for the material’s resistance to environmental factors, such as ozone, UV radiation, and moisture.

- Testing methods: The standard provides guidelines on testing methods and procedures to evaluate the material’s compliance with the specified criteria, ensuring consistency and accuracy in material properties.

- Traceability: AA 59588 may require manufacturers to maintain strict traceability and lot control procedures. This ensures that materials produced in different batches or lots consistently meet the specified criteria.

- Requalification: In some cases, silicone rubber materials may need to undergo requalification at specified intervals or after certain environmental exposures to ensure ongoing compliance.

Industries Governed by AA 59588

Compliance with AA 59588 is not just a regulatory obligation but a strategic imperative. Here are some industries covered by AA 59588 standards:

Aerospace and Defense

AA 59588-compliant silicone rubber materials are indispensable in sealing, insulating, and protecting sensitive components in aerospace applications. These materials must endure extreme temperatures, resist harsh chemicals, and maintain their integrity over time. Non-compliance can result in catastrophic failures, endangering lives and missions.

Automotive

The automotive industry relies on AA 59588 standards to ensure the durability and safety of vehicles. Silicone rubber components that meet these standards are used in critical applications like gaskets, seals, and wiring harnesses. They provide excellent resistance to heat, oil, and environmental factors, enhancing the reliability and longevity of automotive systems.

Electronics

AA 59588-compliant materials are instrumental in safeguarding delicate electronic circuits. Silicone rubber’s electrical insulating properties make it ideal for encapsulating and protecting sensitive components. Adherence to these standards is crucial to prevent malfunctions, fires, and costly recalls.

Healthcare

Silicone rubber materials that follow AA 59588 standards are used in various medical devices and equipment, including seals and gaskets for fluid handling. Compliance is essential to ensure patient safety and the effectiveness of medical treatments.

Renewable Energy

As renewable energy sources like wind and solar power continue to grow, materials guaranteed by AA 59588 standards are becoming more instrumental in component manufacturing for this industry. High-quality products have better longevity and performance, contributing to sustainable equipment use.

ElastaPro: Your Partner for AA 59588 Compliance

Trust ElastaPro Silicone Sheeting for all your silicone rubber material needs! Our AA 59588-compliant products prove our commitment to quality and excellence. With over 20 years of experience, we have solidified ourselves as industry veterans in silicone sheeting, compounding, and technology. Our goal is to maximize exceptional and innovative manufacturing techniques to continuously meet and exceed your expectations.

Contact us today to learn how we can help you meet the highest quality and performance benchmarks for your products.

-

Specs of Silicone and Their Respective Applications

Silicone is a versatile synthetic material composed primarily of silicon, oxygen, carbon, and hydrogen. Its non-reactive nature makes it suitable for diverse applications, including sealants, lubricants, and medical implants. Moreover, its exceptional thermal stability allows it to withstand temperature variations, from freezing to high-temperature industrial processes.

Due to its versatility, silicone comes in different specifications tailored to meet diverse industry requirements. These variations in material formulations allow for customization based on hardness, flexibility, and chemical resistance. Below are some of its most common specifications and their respective applications:

Military Specifications

Here are examples of widely-used silicone mil-specifications:

MIL-DTL-25988

The MIL-DTL-25988 specification is structured to define the parameters and characteristics of fluorosilicone (FVMQ) materials, emphasizing their intended use in aerospace applications. It classifies the materials into various classes, considering factors like tensile strength, elongation, and durometer hardness. It also guarantees that the fluorosilicone meets stringent standards, providing reliability, durability, and performance across military conditions.

MIL-DTL-83528

The MIL-DTL-83528 criterion outlines the specifications for electrically conductive rubber and fluorosilicone gaskets. These products are intended to offer protection against electromagnetic interference (EMI) and radio frequency interference (RFI). They are essential components in instances where shielding against such disruption is required to ensure electronic systems’ integrity and effective operation.

Aviation Specifications

While no specific overarching aviation specifications exist exclusively for silicone, various standards may reference or incorporate silicone-based materials. Here are a few examples:

Lockheed STM23

Lockheed STM23 specifications cover a wide range of silicone chemistry for various mission-critical requirements. Materials such as high-strength VMQ, PVMQ, and FVMQ are used with the Lockhead STM23 specifications. ElastaPro has many materials that meet these requirements.

MIL-PRF-81322

The MIL-PRF-81322 specification outlines general requirements for aircraft turbine engine lubricating oils. It does not specifically focus on silicone, but some lubricants that meet this specification may contain silicone-based additives. These compounds known for their thermal stability and oxidation resistance contribute to the lubricants ability to withstand high temperatures within turbine engines.

AMS

The AMS criterion specifies silicone rubber for use in high-temperature aviation engine seals and gaskets. The material is designed to withstand the extreme conditions encountered in aircraft engines, like elevated temperatures and exposure to aviation fuels. In addition, silicone rubber in various aerospace applications contributes to effective sealing and long-term durability. ElastaPro offers certified materials meeting stringent standards, including 3302, 3303, 3304, 3305, 3315, 3320, 33345, 3337, 3346, 3325, 3332, 3326, 3348, and 3348.

Boeing Material Specifications

Boeing typically employs various industry and international standards for materials. ElastaPro works with key requests such as BMS 1-52, 1-76, 1-57, 1-73 and 1-73.

BMS Solid Silicone Sheet

BMS solid silicone sheets are engineered to meet stringent standards for flexibility, durability, and high resistance to environmental factors. This makes them suitable for diverse aircraft components. They are also utilized in gaskets, seals, and insulation applications, providing reliable performance in challenging aerospace environments.

At ElastaPro Silicone Sheeting, these sheets arrive ready for die-cutting. They are between 0.010” and 0.500” thick and available in widths of up to 60”.

BMS Uncured Silicone Compound

The BMS sets stringent standards for uncured silicone compounds’ right chemical composition and physical properties. This ensures that they meet the specific requirements for aerospace use. By adhering to BMS, manufacturers guarantee that the compounds contribute to producing high-quality and durable aviation components.

Choose ElastaPro Silicone Sheeting for Your Silicone Needs

ElastaPro Silicone Sheeting delivers high-quality silicone products and components to clients across the globe! Our product range spans various solutions, each crafted to meet stringent industry standards and specific application needs. From sheets and gaskets to seals and custom products, we offer versatile options that find applications in numerous industries.

Contact us today for inquiries!

-

Medical Grade Silicone: What Sets It Apart and Why It Matters

Medical grade silicone is a type of silicone that meets specific quality and safety standards suitable for healthcare applications. These materials are often required to meet USP Class VI or ISO 10993 requirements for biocompatibility. It is made using highly purified compounds for biocompatibility, meaning it is unlikely to cause adverse reactions when in contact with the human body. It is also well-known for its durability and resistance to extreme temperatures, making it ideal for medical devices and implants.

Unlike other types, medical grade silicone is subjected to stringent quality control and testing procedures to guarantee it meets the highest purity standards. This article will explore the properties of this synthetic polymer, highlighting why it is exceptionally valuable in the medical industry.

Unique Properties of Medical Grade Silicone

The following features make this component essential in the healthcare industry, ensuring patient safety and well-being:

Biocompatibility

This property is extremely critical in the medical field, as it ensures that the human body has well-tolerated silicone devices and implants. Whether employed in pacemakers, joint replacements, or catheters, the material’s biocompatibility contributes to the overall success of medical interventions.

Chemical and Fluid Resistance

Medical grade silicone is highly resistant to bodily fluids, chemicals, and the sterilization processes commonly performed in healthcare settings. This resistance ensures the tool remains stable and maintains its structural integrity over extended periods. Moreover, its tolerance to various chemicals means it can withstand exposure to disinfectants and medications without deteriorating.

Electrical Insulation

This feature is useful in medical equipment with electronic components. Silicone can efficiently separate and shield delicate circuitry from moisture and external factors, guaranteeing devices’ safe and dependable operation. Examples include defibrillators, infusion pumps, pacemakers, and other diagnostic machines.

Flexibility and Durability

One of silicone’s characteristics is its capacity to be customized to varying levels of flexibility while keeping structural integrity. This feature enables it to resemble the softness of human tissue in medical procedures like breast implants. Its flexibility is also beneficial in prosthetics and tubing, where it needs to conform to the body’s contours or undergo repeated bending.

Hypoallergenic Nature

Because this silicone is hypoallergenic, it is less likely to cause allergic responses when it comes into contact with the skin. This is critical in situations where the material is near the patient, such as wound dressings or skin-contacting medical devices. Patients can be confident that the equipment is compatible with their bodies, lowering the chance of skin irritations or allergies.

Resistance to Bacteria Growth

The silicone’s resistance to bacteria growth is critical in preventing infections when used in medical devices or prosthetics. Its properties make it less conducive to the attachment and proliferation of harmful microorganisms, reducing the risk of device-related diseases. This is particularly essential in implants like urinary catheters or long-term indwelling instruments.

Thermal Stability

Medical grade silicone can withstand extreme temperature fluctuations without losing its qualities. This is especially important in hospitals where sterilization keeps medical devices clean. Autoclaving is a popular disinfection method that involves subjecting instruments and equipment to high-pressure steam at elevated temperatures.

Transparency and Clarity

Some silicone formulations provide optical clarity and transparency. This unique feature benefits ophthalmic applications such as intraocular and contact lenses. The material’s clearness allows for optimal light transmission, improving the quality of vision correction and minimizing distortion.

Choose ElastaPro Silicone Sheeting for Your Silicone Needs

At ElastaPro Silicone Sheeting, we offer high-quality silicone products and services to clients across the globe! Our portfolio encompasses various components, catering to the specific needs of industries such as healthcare, automotive, electronics, and more. We also employ rigorous quality control measures to ensure everything we do meets and exceeds industry standards.

Contact us today to learn more about our solutions!

-

What To Look For With Uncured Silicone Compound

Uncured Silicone Rubber Compounds are used by fabricators to convert into cured articles, through typical thermoset methods of compression, transfere, injection, extrusion and calendering.

Here’s what to look for when dealing with uncured silicone so that your projects are finished to the highest quality and safety requirements:

1. Consistency

Silicone Compound consists of silicone rubber and other key additives such as heat stabilizers, flame retardants, process aids, color, and catalysts. Proper dispersion of these ingredients is critical in ensuring the highest quality fabricated part for optimal functional performance and proper appearance.

2. Color

Uncured Silicone compound is available in a variety of colors. When working with uncured silicone, choose the right color for your project. When color matching, it’s important to match the cured material as uncured material may change color after curing.

3. Shelf-Life/Storage

Various catalyst systems are used in uncured silicone rubber compounds. The fabrication methods determine which catalyst to use. Both Peroxides and Platinum are used and either can be used for extrusion, molding or calendering. Typical shelf life periods are from 90 days to 180 days, depending on the catalyst used. Refrigeration typically helps in extending the shelf life by an additional 50%.

4. Cure Time

Cure time depends on what catalyst and cure temperatures are used, along with the thickness of the fabricated part. Rheological Studies are an effective way to determine the optimal time/temperature combination needed to fabricate a part.

5. Preform

To help facilitate part fabrication, various preforms are available to assist the fabricator in loading their equipment. Performs such as “wig-wag” are used for extrusion, along with “pigs” for injection and sheets or pre cut slabs are also an option. It’s best to consult with your mixer to determine the best performance for your fabrication methods.

Trust ElastaPro for All of Your Uncured Silicone Rubber Needs!

If you’re looking for a high-quality uncured silicone rubber compound, ElastaPro is here to help! Our uncured silicone compound combines the advantages of high-quality silicone rubber with exceptional service and technology. Further, our products are proudly made in the USA and come in various grades, catalysts, durometers, sizes, and colors to meet your needs.

ElastaPro’s specifications grade uncured silicone compound meets industry standards and customer callouts, including 3-A, ASTM, AMS, BMS, DMS, FDA/BgVV, MIL, and MIL-SPEC. We can even provide custom colors to support your larger product designs, with formulations ranging from VMQ and FVMQ to PVMQ and hybrids.

Contact us today to learn more about our uncured silicone compound!

-

How To Choose a Silicone Manufacturer

As the demand for accurate and dependable products increases, so does the need for trustworthy manufacturers. Thus, the first step in ensuring the long-term success of your business is selecting the ideal silicone product manufacturer. However, choosing the right one might take significant work, as the market is crowded with suppliers who claim to be capable of providing your needs.

When looking for the best silicone manufacturer for your company, there are a few factors you should take into account before making a final choice. Here are the four most important considerations:

Choosing the Right Silicone Partner

Here’s a list of things that you should look at when selecting a silicone manufacturer for your business:

Proximity

When selecting a manufacturer for silicone products, proximity is an important consideration. Technological advancements have made it possible to obtain products from around the world, so where you invest your money by sourcing your components is a key decision.

The US is one of the leading producers of silicone goods worldwide and sets the bar for inventive production techniques. Thus, your company may save money in the long run and get an advantage over competitors by using silicone manufactured in the country. These products are guaranteed best quality, and you can leverage better turnaround times and cutting-edge innovation.

Remember that you are establishing a long-term collaboration rather than just looking for a passable manufacturer. Therefore, your main goal should be to select a manufacturer who can supply you with cost-effective and efficient parts.

Track Record

Choosing a silicone manufacturer with a history of success and a solid reputation is always best. Inquire about the types of projects undertaken by potential manufacturers and determine how your project might fit within their experience. Finding a manufacturer specializing in your industry might help you avoid potentially costly errors.

You can also test the performance of the manufacturer’s supplied products. Some producers could charge you a small fee for procuring a sample. Still, it would pay to invest in confirming their products’ caliber; if the quality isn’t up to your requirements, it will save you from larger losses.

Expertise

When looking for the top silicone goods manufacturer, look for skilled employees and management. All employees in the manufacturing company — including designers, quality controllers, engineers, salespeople, and customer service representatives — should be well-qualified and exhibit professional conduct. An experienced team will aid in producing high-quality items that will benefit your company.

Good Communication

A collaborative and respectful attitude with a strong customer service team is crucial in your silicone manufacturing partner. The provider should take the time to understand your business and needs during the design process or after the product has been manufactured. Choosing a manufacturer in the same time zone can also help facilitate communication, especially when dealing with urgent requirements.

ElastaPro Silicone Sheeting: The Right Silicone Manufacturer for You!

Are you looking for the perfect partner that can provide you with the best solution for your silicone needs? Then, ElastaPro is the ideal choice for you!

At ElastaPro Silicone Sheeting, we offer clients worldwide a wide range of silicone products and components. Our significant field expertise and years of accumulated knowledge have enabled us to provide great outcomes to our client partners with various industrial needs.

Contact us today to learn more about our innovative silicone solutions.

-

Solid Silicone Product Considerations

Silicone is primarily made from silica, which contains various chemical components such as carbon, hydrogen, oxygen, and silicon. Solid silicone is a pliable elastomer or rubber ideal for a multitude of applications in the medical, aerospace, automotive, electronics, and food processing industries.

ElastaPro Silicone Sheeting offers a broad spectrum of solid silicone sheeting that our clients can use for a variety of purposes. These solid silicone products are extremely versatile, flame-retardant, durable, heat-resistant, high-performing, and have low chemical reactivity, making them perfect for your solid silicone needs. Our products can be supplied in either cured sheet or uncured sheet (which is used by fabricators to make their own part constructions). There is no elastomer better in maintaining its physical properties across a broad temperature spectrum, than silicone.

ElastaPro’s Solid Silicone Sheeting

At ElastaPro, we provide the finest silicone products by combining the advantages of high-quality silicone rubber with superior service and technology. Our products can be availed in various grades, sizes, colors, and durometers and are proudly made in the USA.

Commercial Grade Solid Silicone Sheet

Ideal for extreme temperature applications, ElastaPro’s commercial-grade solid silicone sheet provides outstanding gasket and sealing solutions for different industries. This product comes in .010″ to .500″ in thickness and up to 60″ in width. It is available in 20-90 durometer, and colors are customizable.

General Purpose Grade Solid Silicone Sheet

Our general-purpose solid silicone sheet has a thickness range of .010″ to .500″ and a width of up to 60″ wide, and meets various key industry specifications. These solid silicone products are designed for general applications and offer extreme temperature resistance and a good compression set. General-purpose grade silicone sheets are available in 25-90 durometer and come in many colors.

FDA Grade (White) Solid Silicone Sheet

This solid silicone product variation is FDA-approved and meets the CFR 177.2600 and European Union requirements, making it ideal for applications involving repetitive food contact. White FDA-grade silicone sheets from ElastraPro have superior gasket and sealing properties, 30-85 in durometer, and have similar thickness and width as other ElastaPro solid silicone products.

FDA Grade (Translucent) Solid Silicone Sheet

Like white FDA-grade silicone, ElastaPro’s translucent solid silicone sheet follows FDA,CFR 177.2600 and European Union requirements to pass industry standards for food processing applications. Although not clear in appearance, it allows light to pass through its rubber component. This product is perfect as a silicone rubber gasket for applications demanding food-grade materials.

Electronically Conductive Solid Silicone Sheet

Typically used in electrical cabinets, PC boards, and RMI/EFI gaskets, this product is a low-amperage semi-conductive silicone ideal for electrical applications. Our electronically conductive solid silicone sheet comes in .020″ to .375″ thickness, and its only color availability is black.

Fiberglass Reinforced Solid Silicone Sheet

The fiberglass-reinforced solid silicone sheet is widely used in aerospace, automotive, and other industries with demanding specifications due to its exceptional weatherability, resistance to various lubricating oils, and can maintain its physical properties over a wide temperature range. This solid silicone sheet comes in two types — specification and commercial-grade fiberglass reinforced.

Fluorosilicone Solid Sheet

With a wide array of available thicknesses and widths, ElastaPro’s fluorosilicone solid sheet is the perfect silicone product for the aerospace, military, and automotive industries. This silicone variation can weather and dilute numerous chemicals, including acids and alkalines, petroleum oils, hydrocarbon fuels, diester, and silicone oils.

Health Care (USP Class VI & ISO 10993) Solid Silicone Sheet

This solid silicone product is specially designed for medical devices and applications that last less than 29 days in the human body and demand additional certification. Our healthcare solid silicone sheets are made-to-order with a range of .010″ to .500″ in thickness and up to 60″ wide.

High Strength Grade Solid Silicone Sheet

High-strength grade silicone sheet is designed for applications that need more robust physical properties. It has FDA CFR 177.2600 certification that guarantees the product can meet high-strength specifications required by various industries.

Medium Strength Grade Solid Silicone Sheet

Available in 25-85 durometers, medium-strength solid silicone sheets are the perfect choice for applications needing higher physical properties than general-grade silicones. This product has a 60″ width and a thickness range of .010″ to .500″.

Extreme Flame Retardant Solid Silicone Sheet

Our Extreme Flame Retardant Grade Silicone Sheeting is designed for applications needing High Flame Resistance, and a UL 94V0 Yellow Card listed material. It is easily die-cut and provides a superior gasket and sealing solution. Thicknesses from .010” to .500” thick. Widths up to 60” wide. Due to the unique chemistries of this material, the product is black in color.

Extreme High-Temperature Solid Silicone Sheet

This product uses the latest Heat Stabilizer Technology to generate higher temperature endurance than standard and general purpose silicone sheets. Extreme high temperature solid silicone sheet is available in a broad spectrum of colors with a .010″ to .500″ thickness range.

Extreme Low-Temperature Solid Silicone Sheet

Contrary to extreme high-temperature silicones, this solid silicone variety is applicable for industries with extremely low temperatures, like aerospace, defense, and cryogenics. This is a made-to-order material and comes in many available colors.

High Strength / Extreme Low Temperature

ElastaPro’s high strength / extreme low temperature is a silicone sheet designed for aerospace, defense, and cryogenics industries that demand high tensile strength and endurance to extremely low temperatures.

Metal Detectable Silicone Sheet

For industry applications that require additional safety — like food, beverage, dairy, pharmaceutical, and others — our metal-detectable silicone sheet is the best silicone choice as it boosts safety and lowers downtime by quickly sequestering seal fragments in-process. This product is available in opaque colors.

Need Solid Silicone Supplies?

ElastaPro Silicone Sheeting provides a vast array of silicone specifications to our clients worldwide. Our extensive field experience and years of acquired knowledge allowed us to deliver outstanding results to our customer partners with varying industrial requirements.

Whatever your silicone needs are, ElastaPro can help! Contact us today to learn more about our innovative silicone solutions.

-

Key Considerations in FDA Silicone Materials

Safety should always be the highest priority for food manufacturers. A single error in handling and packaging could result in a negative brand image and the consumers losing their trust in the brand. Over the years, different materials — like glass, metal, wood, plastic, rubber, and silicone — have been used to seal, store, hold, pack, and transport food items domestically and internationally. However, a particular material stands out above the rest.

FDA-approved silicone materials are widely used around the globe due to the numerous benefits they offer to their users. In addition, companies and food manufacturers often choose this type of silicone for their business operations because of its versatility and high-performing features.

FDA silicone materials are multifaceted and robust synthetic polymers. These products have low volatility, and no odor or taste, making them ideal for direct and repetitive food contact. Still, manufacturers must adhere to specific FDA standards for safety and handling to achieve the FDA food-grade label.

This article discusses why manufacturers should consider switching to FDA silicone materials for food packaging and sealing needs.

Benefits of FDA Silicone Materials

FDA-grade silicone materials are durable and adaptable, enabling manufacturers to utilize them in multiple applications. One of its best qualities is resistance to external elements like extreme heat and stressful environments. Because of this, it is widely used in producing gaskets and seals for food packaging. Below are the many other advantages of using FDA-approved silicone products.

Resistance to Extreme Temperature

Silicone is known for its heat endurance qualities. It can withstand extreme hot and cold temperatures, ranging from -80 °F to 550 °F, without yielding its durability and shape. Silicone developed its low thermal conductivity due to its highly stable chemical structure.

Resistance to Liquid and Chemicals

Silicone is not only heat resistant but also watertight. It also can resist food oils and most chemical types. Thus, food containers sealed using FDA silicone materials prevent leakage and food contamination.

Resistance to Environmental and External Elements

Because of their durability, FDA silicone materials can repel environmental and external elements like aging, ozonation, and weathering. This specific silicone feature helps foods sealed in silicone gaskets prolong their shelf life.

Free of Harmful Fillers

Some food containers and sealers contain toxic organic compounds like Bisphenol S and A (BPS, BPA) that could lead to increased blood pressure, cardiovascular diseases, type 2 diabetes, and other hormonal and obesogenic effects. Fortunately, silicones are non-toxic materials safe for food sealing and packing purposes.

Prevents Unwanted Physical Changes

Due to its food-grade status, silicone materials are less vulnerable to discoloration, deformation, odor, and other unwanted changes that could result in food contamination, making them unsuitable for consumption. Subsequently, they have antifungal and nonstick properties that help prevent mold or fungal decay.

Flexibility

Silicone’s flexible nature allows manufacturers to transform and mold it into custom sealing profiles, extending its usability to a broader spectrum of food applications.

FDA Silicone Food Applications

FDA-grade silicone materials have extensive functions and can be applied to several food-related purposes:

- Gaskets for food processing machinery

- Food transfer tubing

- Dairy tubing and fluid handling

- Vending tubing

- Brewery tubing and seals

- Antimicrobial belting

- Commercial oven seals

- Coffee machine tubing

- Food-grade beverage gaskets

- O-rings

- Vibration pads

- Electrical insulators

Get Exceptional FDA Silicone Materials From ElastaPro

Food safety doesn’t stop with food processing. Manufacturers should also consider using food-grade materials to keep their products fresh and free from harmful substances.

ElastaPro offers durable FDA-approved silicone sheeting ideal for making trustworthy silicone rubber gaskets and seals for safe and secured food packaging. Our products come in two varieties — FDA Grade (Translucent) Silicone Solid Sheet and GDA Grade (Pigmented) Silicone Sheet — and are compliant with CFR 177.2600, a section of the U.S. Code of Federal Regulations (CFR) with components for rubber articles intended for replicated use in contact with food.

Do you need a reliable FDA silicone materials supplier for your business? Partner with us today! ElastaPro has been around in the industry for decades, making us one of the silicone sheeting, compounding, and technology experts.

Contact us and get your high-quality FDA silicone from us!

-

Where To Find High Temperature Silicone

Since silicone can endure up to approximately 300 °F, this material is the preferred rubber for applications requiring tolerance to extreme temperatures. Although commercial silicones are generally heat-resistant, there are silicone products that are specifically formulated to resist temperatures of 500-572 °F without sustaining deformation or other damages.

Silicone’s highly stable chemical structure makes it thermal resistant while offering a kaleidoscope of advantageous properties, including high flexibility, water resistance, electrical insulation properties, and compounds to resist mold and fungus growth. In this article, we will go over the different types of silicone rubber and the industries and applications where they are commonly used.

Types of Silicone Rubber

Silicone rubber’s flexibility is thanks to groups of organic molecules formed on a base of silicon and oxygen. It is available in various forms, each with distinctive attributes suitable for a range of applications.

Methyl Groups (MQ)

This group is known as dimethyl silicone rubber or methyl silicone rubber. Methyl groups can be substituted with other groups — including ethyl, phenyl, and vinyl — to enhance and modify their mechanical, chemical, and thermodynamic properties for different applications.

Methyl and Vinyl Groups (VMQ)

This group, known as methyl vinyl silicone rubber, is the most commonly used type. It features good compressive strength, which helps with the vulcanization industry. This type also has excellent low-temperature flexibility, high heat, and oxidative stability and is resistant to chemicals, corrosion, ozone, and sunlight.

Methyl and Phenyl Groups (PMQ)

This silicone rubber group, known as methyl-phenyl silicone rubber or phenyl silicone rubber, has an excellent low-temperature performance. The presence of phenyl enhances different properties, including high corrosion resistance, thermal stability, shear resistance, and optical conciseness. This group is used for connectors in the cable industry and sealing for automotive and aerospace applications.

Methyl, Phenyl, and Vinyl Groups (PVMQ)

The methyl groups in this compound are substituted with phenyl groups, which effectively enhances the material’s low operating temperatures. As a result, they are particularly suited to hygienic applications in the food and pharmaceutical industries.

Fluoro, Vinyl, and Methyl Groups (FVMQ)

This group is also known as fluorinated rubber or fluorosilicone rubber. They are highly chemically resistant to fuel, oil, and solvent substances. They are also typically used in sealing applications in the aerospace industry that require resistance to hot fuels, oils, and diester-based lubricants.

Uses and Applications of High Temperature Silicone Rubber

Because high temperature silicone rubber is so robust and offers the best performance of any elastomer across the extreme temperatures, , it is used in many critical applications.. Here are some of its uses and applications:

Hot Stamping

Silicone rubber sheets are extensively used in consumer product decoration, particularly hot stamps, heat seals, or heat transfer. For example, sheets are used in hot stamp decoration for full coverage and tipping applications. An example of tipping is when the foil is used to raise lettering on credit cards. Meanwhile, standard silicone sheets enable contact for applying the full image on a heat transfer mark to a part in heat transfer decoration.

Electronic Equipment

Silicone rubber is used to manufacture electrical insulating tapes, adhesives, sealants, circuit board surface coatings, varnishes, lubricants, optical fiber coatings, and other silicon-grade and silicon-source chemicals. It is also used in making keyboards, telephones, hard-coating computer housings, and other electronic equipment.

Automotive Industry

Silicone rubber sheets — resistant to heat, oil, and fuel — are molded into various durable parts for the automotive industry. These include sealants and adhesives, specialty lubricants, vibration components, and automotive polishes.

Aerospace Equipment

Silicone rubber is applied in many aspects of aircraft assembly and maintenance. Mainly, it is used in manufacturing ablatives, window seals, boots, hoses, seals and gaskets, and adhesives.

Construction Industry

Silicone rubber is used in many applications in constrcution from sealing, to protecting. Due to silicone’s excellent ability to resit the elements its the premier material for construstion sealing.

Choose ElastaPro for Your Silicone Needs!

ElastaPro was founded by industry veterans with decades of knowledge and expertise in silicone sheeting, compounding, and technology. We are fueled by our desire and deep expertise in effectively utilizing exceptional and proprietary manufacturing techniques to meet our customers’ requirements.

Contact us today to learn more about our silicone products and services!