Manufacturers follow a set of industry standards and criteria that ensure materials and processes meet rigorous requirements. One such standard that plays a pivotal role in guiding material compliance is AA 59588. This is a specification document issued by the United States Department of Defense (DoD). Its primary purpose is to establish the requirements for silicone rubber materials used in various applications especially those involving extreme conditions and stringent performance demands.

In this blog post, we’ll take a closer look at AA 59588, exploring its criteria standard and its profound impact on various industries.

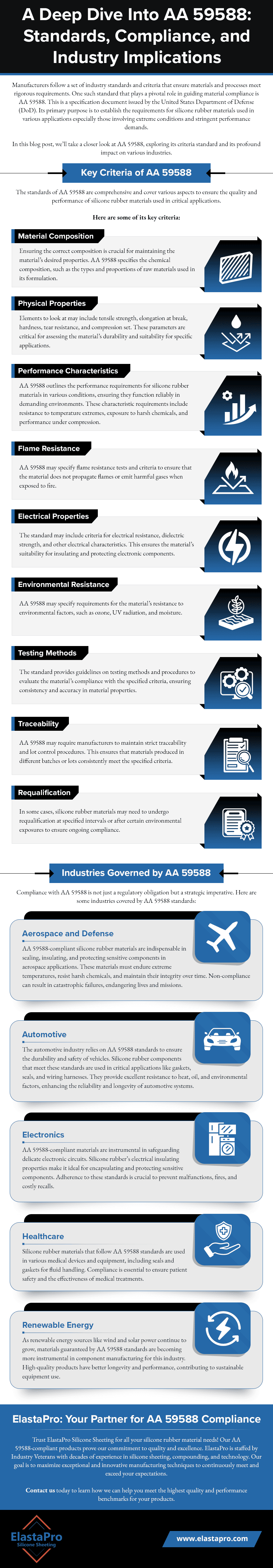

Key Criteria of AA 59588

The standards of AA 59588 are comprehensive and cover various aspects to ensure the quality and performance of silicone rubber materials used in critical applications. Here are some of its key criteria:

- Material composition: Ensuring the correct composition is crucial for maintaining the material’s desired properties. AA 59588 specifies the chemical composition, such as the types and proportions of raw materials used in its formulation.

- Physical properties: Elements to look at may include tensile strength, elongation at break, hardness, tear resistance, and compression set. These parameters are critical for assessing the material’s durability and suitability for specific applications.

- Performance characteristics: AA 59588 outlines the performance requirements for silicone rubber materials in various conditions, ensuring they function reliably in demanding environments. These characteristic requirements include resistance to temperature extremes, exposure to harsh chemicals, and performance under compression.

- Flame resistance: AA 59588 may specify flame resistance tests and criteria to ensure that the material does not propagate flames or emit harmful gases when exposed to fire.

- Electrical properties: The standard may include criteria for electrical resistance, dielectric strength, and other electrical characteristics. This ensures the material’s suitability for insulating and protecting electronic components.

- Environmental resistance: AA 59588 may specify requirements for the material’s resistance to environmental factors, such as ozone, UV radiation, and moisture.

- Testing methods: The standard provides guidelines on testing methods and procedures to evaluate the material’s compliance with the specified criteria, ensuring consistency and accuracy in material properties.

- Traceability: AA 59588 may require manufacturers to maintain strict traceability and lot control procedures. This ensures that materials produced in different batches or lots consistently meet the specified criteria.

- Requalification: In some cases, silicone rubber materials may need to undergo requalification at specified intervals or after certain environmental exposures to ensure ongoing compliance.

Industries Governed by AA 59588

Compliance with AA 59588 is not just a regulatory obligation but a strategic imperative. Here are some industries covered by AA 59588 standards:

Aerospace and Defense

AA 59588-compliant silicone rubber materials are indispensable in sealing, insulating, and protecting sensitive components in aerospace applications. These materials must endure extreme temperatures, resist harsh chemicals, and maintain their integrity over time. Non-compliance can result in catastrophic failures, endangering lives and missions.

Automotive

The automotive industry relies on AA 59588 standards to ensure the durability and safety of vehicles. Silicone rubber components that meet these standards are used in critical applications like gaskets, seals, and wiring harnesses. They provide excellent resistance to heat, oil, and environmental factors, enhancing the reliability and longevity of automotive systems.

Electronics

AA 59588-compliant materials are instrumental in safeguarding delicate electronic circuits. Silicone rubber’s electrical insulating properties make it ideal for encapsulating and protecting sensitive components. Adherence to these standards is crucial to prevent malfunctions, fires, and costly recalls.

Healthcare

Silicone rubber materials that follow AA 59588 standards are used in various medical devices and equipment, including seals and gaskets for fluid handling. Compliance is essential to ensure patient safety and the effectiveness of medical treatments.

Renewable Energy

As renewable energy sources like wind and solar power continue to grow, materials guaranteed by AA 59588 standards are becoming more instrumental in component manufacturing for this industry. High-quality products have better longevity and performance, contributing to sustainable equipment use.

ElastaPro: Your Partner for AA 59588 Compliance

Trust ElastaPro Silicone Sheeting for all your silicone rubber material needs! Our AA 59588-compliant products prove our commitment to quality and excellence. With over 20 years of experience, we have solidified ourselves as industry veterans in silicone sheeting, compounding, and technology. Our goal is to maximize exceptional and innovative manufacturing techniques to continuously meet and exceed your expectations.

Contact us today to learn how we can help you meet the highest quality and performance benchmarks for your products.