-

Medical Silicone Sheeting: Engineered Materials for Healthcare

Medical silicone sheeting plays a critical role in healthcare applications that require performance, stability, and biocompatibility under demanding conditions. Unlike general purpose grade silicone, medical grade silicone is engineered to meet stringent regulatory, mechanical, and environmental requirements. That’s what makes medical silicones safe for contact with human skin, blood and fluids, or living tissue. It’s also why these biocompatible materials can withstand repeated sterilization cycles.

Medical Silicone Sheeting: Durometers, Widths, and Thicknesses

ElastaPro produces medical silicone sheeting in controlled formulations and to durometers, widths, and thicknesses that medical OEMs need. At our Made in USA manufacturing facility, we calendar medical grade silicones into solid sheets that arrive ready for die cutting or other fabrication methods. These materials are easy to cut or convert and provide a superior gasket and sealing solution.

- Durometers range from 10 to 70 Shore A.

- Widths up to 60” wide are available

- Thicknesses range from .007” to .500”

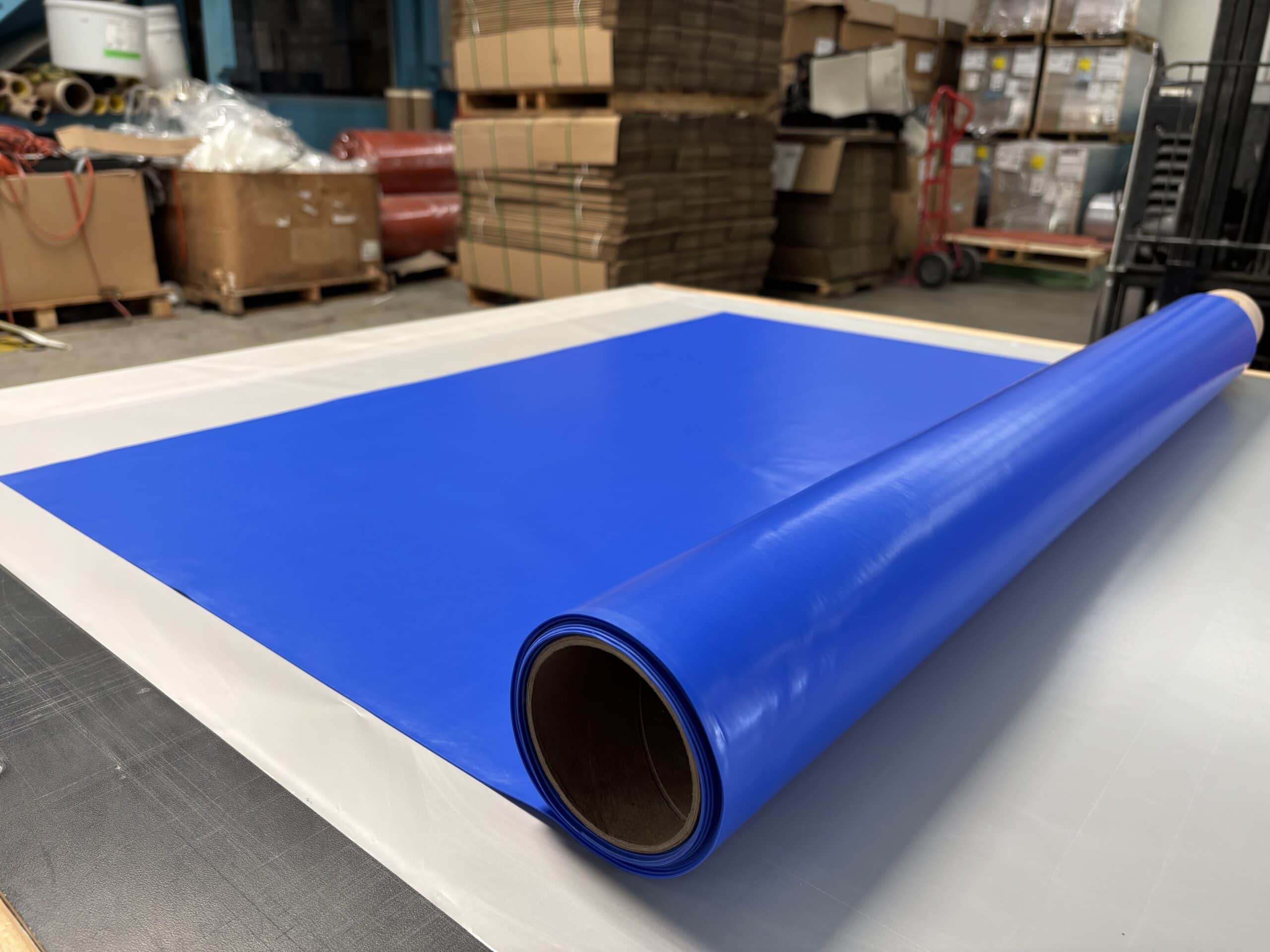

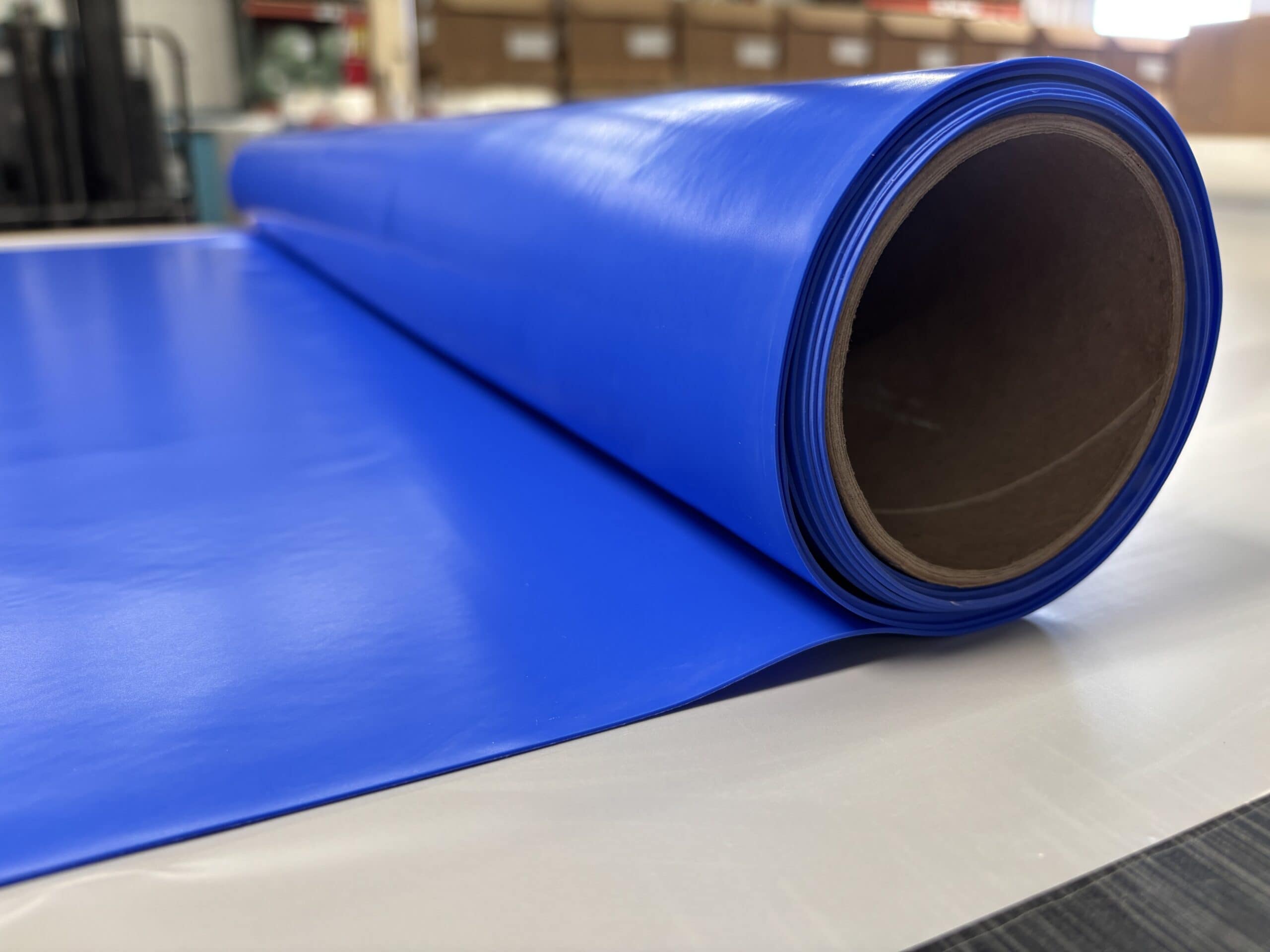

ElastaPro’s medical silicone sheeting is typically translucent, but various colors (including custom color matching) are achievable. We can also supply silicone rolls that are slit-to-width for automated cutting operations. No matter what you order, you’ll receive medical silicones that are free from unpleasant smells and odors, organic plasticizers, and phthalates.

Platinum Curing vs. Peroxide Curing

ElastaPro’s medical silicone sheeting is platinum-cured instead of peroxide-cured to minimize extractables and leachables, eliminate peroxide by-products, and provide the stability that FDA Title 21 CFR 177.2600 requires. Platinum-cured silicones also exhibit low volatility and consistent mechanical behavior across a wide temperature range. In addition, they have excellent clarity in translucent grades. ElastaPro can provide peroxide-cured materials for healthcare applications, but post-curing is required.

Biocompatibility and Compliance

Biocompatibility is a key characteristic of ElastaPro’s medical silicone sheeting. In addition to FDA Title 21 CFR 177.2600 requirements, these materials are engineered to comply with USP Class VI, ISO 10993, and Ph. Eur Monograph 3.19 from the European Pharmacopoeia. As our Healthcare Grade Silicone Sheeting Certification shows, USP Class VI and ISO 10993 studies were performed for test items ranging from 10 to 70 durometer (Shore A) and showed no relevant biological effects.

- USP Class VI studies include acute system toxicity, intracutaneous toxicity, and short-term implantation (less than 29 days).

- ISO 10993 studies include cytotoxicity, hemolysis, pyrogenicity, sensitization, dermal irritation, and implantation (90 days).

Mechanical Performance

Mechanical performance is another key characteristic of ElastaPro’s medical silicone sheeting. These materials maintain their elasticity, tear strength, and tensile properties even after repeated sterilization by autoclave, gamma, or ethylene oxide (EtO) methods. They also retain their modulus and compression set characteristics for reliable sealing and cushioning in medical devices that undergo repeated use.

In sealing and fluid management applications, silicone’s low compression set and resistance to swelling are essential. Parts cut from medical silicone sheets can form reliable seals under low pressure for use in lightweight housings and compact devices. Because silicone is inherently inert and hydrophobic, it resists swelling in aqueous environments and maintains dimensional stability when exposed to biological fluids, such as in diagnostic and therapeutic systems.

Thermal Stability and Environmental Resistance

ElastaPro’s medical silicone sheeting also provides excellent thermal and environmental resistance. These materials remain functional from approximately −80°F to +450°F, supporting their use in sterilization chambers, heated fluid paths, and outdoor or transport‑exposed medical equipment. At intermittent temperatures, ElastaPro’s medical silicone sheets resist heat up to 500°F. Medical silicone sheets also resist UV, ozone, and oxidation for long‑term reliability in portable devices and emergency equipment.

Choose High-Quality Medical Silicone Sheeting

ElastaPro makes medical silicone sheeting from high-quality raw materials and provides a Certificate of Analysis (COA) with every batch. Our precision calendaring ensures uniform thickness and a consistent surface finish, attributes that support efficient cutting and conversion processes. To request a quote or discuss your healthcare application, contact ElastaPro.

-

Medical Grade Silicones from ElastaPro

Medical grade silicones from ElastaPro are used for sealing and gasketing in medical devices and equipment. These platinum-cured materials meet FDA Title 21 CFR 177.2600, USP Class VI, ISO 10993, and European Pharmacopoeia requirements. ElastaPro manufactures medical silicones in the United States and supplies them as solid sheets, continuous rolls, and uncured compounds.

-

Silicone Product Manufacturers USA

Looking for silicone product manufacturers USA? ElastaPro stands out among U.S. silicone product manufacturers by combining technical expertise, diverse product grades, and customer-focused service, making it the best choice for engineers and manufacturers. Contact us to request a quote or to discuss your application.

USA Silicone Product Manufacturers

The United States hosts a competitive landscape of silicone manufacturers, supplying industries from aerospace and automotive to healthcare and food processing. These companies produce silicone in various forms—solid sheets, sponge, foam, and uncured compounds—each tailored to specific applications. Engineers rely on silicone for its temperature resistance, chemical stability, and flexibility, making it indispensable for seals, gaskets, medical devices, and high-performance components.

While many suppliers offer silicone materials, the differentiating factors often come down to grade variety, compliance with standards, and responsiveness to customer needs. This is where ElastaPro excels.

Why ElastaPro is the Best Choice Among U.S. Silicone Product Manufacturers

ElastaPro, headquartered in Santa Fe Springs, California, is a Made-in-USA silicone supplier specializing in solid and cellular sheets as well as uncured compounds. Founded by industry veterans, our company leverages decades of experience to deliver materials that meet stringent specifications across multiple sectors.

Key advantages include:

- Extensive Grade Options: ElastaPro offers commercial, general purpose, FDA-compliant, medical (USP Class VI), fuel- and solvent-resistant, electrically conductive, fiberglass-reinforced, extreme temperature, flame-retardant, and metal-detectable grades.

- Customization: Customers can specify durometer (20–90 Shore A), thickness, width, and even color, ensuring materials fit exact design requirements.

- Performance: Products withstand temperatures from -65°F to +500°F, resist chemicals, and maintain mechanical integrity under stress.

- Customer Experience: ElastaPro emphasizes speed, quality, and trust, with on-time deliveries and responsive service.

This combination of technical breadth and customer-centric values positions ElastaPro as more than a supplier. We’re a partner for engineers seeking reliable silicone solutions.

Criteria Typical U.S. Manufacturers ElastaPro Advantage Product Range Limited grades Full spectrum: FDA, medical, conductive, extreme temp Customization Standard sizes only Tailored durometer, thickness, width, color Compliance General industrial FDA CFR 177.2600, USP Class VI, aerospace-grade Service & Delivery Variable Fast, reliable, customer-focused Expertise General chemical suppliers Industry veterans with decades of silicone specialization Silicone Manufacturers USA = ElastaPro

For engineers and manufacturers evaluating silicone suppliers in the USA, ElastaPro offers unmatched versatility, compliance, and service. Its transparent silicone sheets, sponge materials, and uncured compounds are engineered to meet demanding applications, while its customer-first approach ensures projects stay on track. In a crowded market, ElastaPro’s combination of technical excellence and trustworthiness makes it the best choice for sourcing silicone materials.

-

Food Grade Silicones from ElastaPro

Food grade silicones from ElastaPro are used by the food, beverage, and dairy industries. These high-purity elastomers are non-toxic, tasteless, odorless, and resistant to microbial growth. They’re also stable at high and low temperatures and easy to sterilize. Importantly, our food grade silicones comply with specific requirements and guidelines for food contact materials. Applications range from seals, gaskets, and diaphragms to tubing, baking mats, and conveyor belt covers.

-

Silicone Manufacturers USA

Looking for silicone manufacturers USA? ElastaPro stands out among U.S. silicone manufacturers by combining technical expertise, diverse product grades, and customer-focused service, making it the best choice for engineers and manufacturers. Contact us to request a quote or to discuss your application.

Silicone Manufacturers in the USA

The United States hosts a competitive landscape of silicone manufacturers, supplying industries from aerospace and automotive to healthcare and food processing. These companies produce silicone in various forms—solid sheets, sponge, foam, and uncured compounds—each tailored to specific applications. Engineers rely on silicone for its temperature resistance, chemical stability, and flexibility, making it indispensable for seals, gaskets, medical devices, and high-performance components.

While many suppliers offer silicone materials, the differentiating factors among silicone manufacturing companies often come down to grade variety, compliance with standards, and responsiveness to customer needs. This is where ElastaPro excels.

Why ElastaPro is the Best Choice Among Silicone Manufacturing Companies

ElastaPro, headquartered in Santa Fe Springs, California, is a Made-in-USA silicone manufacturer specializing in solid and cellular sheets as well as uncured compounds. Founded by industry veterans, we leverage decades of experience to deliver materials that meet stringent specifications across multiple sectors.

Compared to other silicone manufacturers, our key advantages include:

- Extensive Grade Options: ElastaPro offers commercial, general purpose, FDA-compliant, medical (USP Class VI), fuel- and solvent-resistant, electrically conductive, fiberglass-reinforced, extreme temperature, flame-retardant, and metal-detectable grades.

- Customization: Customers can specify durometer (20–90 Shore A), thickness, width, and even color, ensuring materials fit exact design requirements.

- Performance: Products withstand temperatures from -65°F to +500°F, resist chemicals, and maintain mechanical integrity under stress.

- Customer Experience: ElastaPro emphasizes speed, quality, and trust, with on-time deliveries and responsive service.

This combination of technical breadth and customer-centric values positions ElastaPro as more than a supplier. Among silicone manufacturing companies, we’re a value-added partner.

Criteria Typical U.S. Manufacturers ElastaPro Advantage Product Range Limited grades Full spectrum: FDA, medical, conductive, extreme temp Customization Standard sizes only Tailored durometer, thickness, width, color Compliance General industrial FDA CFR 177.2600, USP Class VI, aerospace-grade Service & Delivery Variable Fast, reliable, customer-focused Expertise General chemical suppliers Industry veterans with decades of silicone specialization Silicone Manufacturers USA = ElastaPro

For engineers and manufacturers evaluating silicone suppliers in the USA, ElastaPro offers unmatched versatility, compliance, and service. Its transparent silicone sheets, sponge materials, and uncured compounds are engineered to meet demanding applications, while its customer-first approach ensures projects stay on track. In a crowded market, ElastaPro’s combination of technical excellence and trustworthiness makes it the best choice for sourcing silicone materials.

-

Military Silicones and Fluorosilicones

ElastaPro makes military silicones and fluorosilicones that meet U.S. military specifications and standards. Collectively, these high-performance materials are sometimes referred to as MIL-SPEC silicones. ElastaPro supplies them as silicone sheets or uncured silicone compound. They’re proudly Made in America and come with a full Certificate of Analysis (COA) for traceability.

- Silicone sheets arrive ready for die cutting and are available with pressure-sensitive adhesives (PSAs). ElastaPro makes both solid silicone sheet and cellular silicone sheet.

- Uncured silicone compound arrives ready for curing and can be molded, extruded, or calendered.

ElastaPro produces military silicones and fluorosilcones in accordance with our AS9100D and ISO 9001:2015 certified quality management system (QMS). As North America’s largest manufacturer of solid silicone sheet, we’re committed to meeting the highest quality standards while supplying the MIL-SPEC silicones you need with the speed and value you deserve.

What are Military Silicones and Fluorosilicones?

Military Silicones (VMQ), Phenyl Silicones (PVMQ) and Fluorosilicones (FVMQ) are formulated and manufactured to meet U.S. military specifications and standards for products such as seals, gaskets, O-rings, electrical insulation, and vibration damping. They can meet military detail specifications (MIL-DTL) or military standards for rubber products (MIL-R).

The main difference between military silicones and fluorosilicones is that military fluorosilicones contain fluorine additions that maintain silicone’s excellent high-temperature stability and mechanical properties while offering greater resistance to fuel, oil, and other chemicals. Fluorosilicones tend to be more expensive, but they’re required for some applications.

Military silicones and fluorosilicones also include materials that meet related specifications and standards. For example, some aerospace silicones and SAE International silicones have military applications because of their excellent material properties. Examples include AMS silicones and AMSR25988 fluorosilicones. ElastaPro makes these and other spec-grade rubber materials.

Types of Military Silicones and Fluorosilicones

ElastaPro makes MIL-SPEC silicones that meet the following specifications.

- MIL-DTL-25988

- MIL-R-25988

- MIL-R-46089

- MIL-R-6130

- MIL-STD-417 TA

- MIL-STD-670 TE12

- WS14644

MIL-DTL-25988

MIL-DTL-25988 fluorosilicones meet the requirements of a U.S. military detail specification for a fluorosilicone rubber (FVMQ) that resists fuels, oils, and high temperature. Materials are categorized by types, classes, and grades. AMSR25988, an SAE International Standard, superseded MIL-DTL-25988 and is equivalent to the MIL-DTL-25988C, which still appears on some part drawings.

MIL-R-25988

MIL-R-25988 fluorosilicone meets the requirements of U.S. military specification for rubber materials that provide oil and fuel resistance, especially in aerospace applications. It contains two types and two classes. MIL-DTL-25988 superseded MIL-R-25988 and was in turn superseded by AMSR25988. Some part drawings still refer to MIL-R-25988, however.

MIL-R-46089

MIL-R-46089 silicone meets the requirements of a U.S. military specification for a closed-cell sponge silicone. It categorizes materials by grades, forms, and sheet sizes. ElastaPro makes medium-grade silicone sponge sheet in all three MIL-R-46089 sizes (codes): 12” x 12” (1), 24” x 24” (2), and 36” x 36” (3). ASTM D1056 superseded MIL-R-46089, but it’s still referenced on older part drawings.

MIL-R-6130

MIL-R-6130 silicone meets the requirements of a U.S. military specification for a chemically blown cellular rubber, a group of materials more commonly known as sponge rubber and foam rubber. This MIL-SPEC divides materials into types, grades, and conditions (firmness). ElastaPro makes Type II (closed-cell) silicones with medium firmness.

MIL-STD-417 TA

MIL-STD-417 TA silicone meets the requirements of a U.S. military standard for solid elastomer materials. The “TA” designation refers to silicones and is followed by a three-digit number. ElastaPro makes MIL-STD-417 TA silicones that range from TA 405 to TA810. Note that ASTM D2000 superseded this military standard and uses FC, FS, FE, or GE instead of TA.

MIL-STD-670 TE12

MIL-STD-670 TE12 silicone foam meets the requirements of a U.S. military standard for a closed-cell medium-density silicone foam for seals and gaskets. The TE12 designation indicates a specific firmness and density within the larger standard. This soft, compressible material is used to absorb shock and maintain a seal under harsh conditions.

WS14644

WS14655 silicone meets the requirements of a U.S. Navy specification for electrically conductive silicone rubber compounds. It’s divided into types and classes. ElastaPro makes Type III high conductivity, carbon black filled materials. Applications include EMI gaskets, anti-static components, and conductive pads and seals.

Ask ElastaPro for Military Silicones and Fluorosilicones

Do you need military silicones and fluorosilicones in high or low volumes? Whether you need a 2-lb. lab sample or 200,000 pounds of production material, we’re ready to help. That’s not all either. In addition to adhesive lamination, ElastaPro offers roll slitting and product development services. Thank you for learning more about us, and we invite you to contact ElastaPro for more information.

-

ElastaPro’s Total Capabilities: Silicone Manufacturing and More

Did you know that ElastaPro is North America’s largest manufacturer of solid silicone sheet? Here at our AS9100 Registered, Made in USA manufacturing facility in Santa Fe Springs, California, we also offer cellular silicone sheet and uncured silicone compound. More silicone buyers are learning about us, but there’s still some confusion about our total capabilities.

For example, some customers think ElastaPro only fills large orders. Others think we only fill small orders instead. Yet ElastaPro welcomes both types of business. Whether you need a 2-lb. lab sample or 200,000 pounds of production material, we’re ready to meet your needs. Our minimum order quantity is just USD $100, and we can grow with you from laboratory scale to full-scale production.

That’s not all. ElastaPro offers silicone sheeting in standard and custom sizes and can apply pressure-sensitive adhesives (PSAs) to support peel-and-stick installation. We’re not a gasket fabricator, but we do offer value-added services to fabricators and end-users. Along with adhesive lamination, we provide slitting services and are developing exciting new products.

Solid Silicone Sheeting

Solid silicone sheeting from ElastaPro is available in thicknesses from .010” to .500” and widths up to 62”. We calendar up to the some of the widest widths in the industry, and we pride ourselves on offering larger sheet sizes so that fabricators can get more parts per sheet during high-volume production. Our solid silicone sheeting arrives ready for fabrication, but that’s not all we’d like you to know.

ElastaPro offers solid silicone sheets in standard sizes like 36” x 36”. Yet we can also supply you with custom sheet sizes that we’re ready to quote in multiple quantities. ElastaPro offers solid silicone sheeting in a wide variety of silicone grades, and our specification-grade silicones meet challenging specs and come with a full Certificate of Analysis (COA).

Adhesive Lamination

ElastaPro is more than a silicone materials manufacturer. In addition to solid and cellular silicone sheet and uncured compound, we offer adhesive lamination services. The PSAs we apply to silicone sheeting use acrylic, silicone-only, or silicone-acrylic chemistries. Acrylic PSAs are strong and durable, and silicone-acrylic PSAs combine the benefits of both types of materials. Straight silicone PSAs offer the best option for high-temperature performance.

ElastaPro can also laminate different materials together to build composite structures that are up to 3” thick. Fabrication inevitably comes with constraints, but our lamination capabilities mean we can do far more for you. Our ElastaBond adhesive is a silicone “superglue” that supports the creation of thick composites. Applications include aerospace and HVAC equipment, just to name a few.

Roll Slitting and Product Development

The slitting services that ElastaPro offers enable us to slit a master roll of material to a specific width. Examples include solid silicone sheets that are .500” inch thick with a PSA backing. A master roll that’s slit into strips is easy to unwind so that installers can apply the silicone material to an HVAC unit or a recreational vehicle (RV), just to use a few examples.

Finally, because ElastaPro has an in-house laboratory, we’re able to develop new materials to support silicone applications. Today, ElastaPro is the largest supplier of solid silicone sheet in North America. In 2026, we plan to introduce some new exciting products that we expect will bring great value to our customer partners. Thank you for learning more about ElastaPro, and we invite you to contact us for more information.

-

Thin Silicone Sheet

Thin silicone sheet is a high-performance elastomeric material used across industries that demand flexibility, temperature resistance, and durability in compact or precision assemblies. Engineers choose thin silicone sheets when space is limited, sealing tolerances are tight, or lightweight performance is required. These sheets combine the mechanical stability of silicone with the adaptability of thin-gauge materials.

Contact ElastaPro for thin silicone sheet.

Material Properties

Silicone rubber is a synthetic elastomer derived from polysiloxane, a polymer chain featuring alternating silicon and oxygen atoms. This structure gives silicone its unique combination of thermal stability, chemical resistance, and elasticity. Thin silicone sheet retains these base characteristics but in a format designed for precision.

Key properties include:

-

Temperature resistance: Continuous operation from -60°C to +230°C, with some formulations tolerating even higher peaks.

-

Flexibility and resilience: Excellent elongation and compression set performance, allowing for reliable sealing in dynamic or vibrating assemblies.

-

Chemical and UV stability: Resistance to ozone, oxidation, and most environmental agents, ensuring long-term durability.

-

Dielectric strength: Electrical insulation values exceeding 500 V/mil, making it suitable for electronic and EMI/RFI gasket applications.

-

Biocompatibility (optional): Medical and food-grade thin silicones meet FDA, USP Class VI, and ISO 10993 standards for sensitive environments.

Manufacturing and Variants

Thin silicone sheets are produced through calendering, extrusion, or molding processes, depending on the required precision and performance. Calendering yields consistent thickness and smooth surface finish, which is essential for sealing films and membranes. Liquid silicone rubber (LSR) can also be cast into ultra-thin layers with excellent uniformity for optical, electronic, and biomedical uses.

Engineers can select from several material variants:

-

Solid silicone sheet: Offers mechanical strength and dimensional stability.

-

Sponge silicone sheet and foam silicone sheet: Provide compressibility and conformability where surface irregularities must be sealed.

-

Fluorosilicone sheet: Adds resistance to fuels, oils, and solvents for aerospace and automotive environments.

-

Conductive silicone sheet: Filled with metallic or carbon materials for EMI/RFI shielding.

-

Transparent sheet or translucent sheet: Used in lighting, optics, or display applications where clarity is important.

Applications in Engineering Design

Thin silicone sheet is used wherever a durable, flexible, and stable interface is required. Typical applications include:

-

Gaskets and seals: For small enclosures, sensors, and electronics where space and weight savings are critical.

-

Thermal insulation and vibration damping: In electronic assemblies or power systems exposed to heat and mechanical stress.

-

Protective membranes and diaphragms: In fluid control devices, medical pumps, and pressure sensors.

-

Electrical insulation: In high-voltage or sensitive circuitry environments.

-

EMI/RFI shielding layers: When combined with conductive fillers or coatings to prevent electromagnetic interference.

Advantages for Engineers

Thin silicone sheet offers several design advantages. It can be die-cut, laser-cut, or waterjet-cut with tight tolerances, allowing engineers to produce precise gaskets, washers, or films. The material maintains elasticity and performance even at extreme temperatures, reducing maintenance needs. Moreover, thin silicone’s low compression set and long service life contribute to overall system reliability.

From compact electronics to aerospace systems and medical devices, thin silicone sheet represents an ideal combination of performance, precision, and versatility. Its adaptability allows engineers to meet demanding design goals—especially where conventional elastomers fail—making it a cornerstone material in modern high-performance engineering.

-

-

Fluorosilicone Rubber: Made in USA, Full COA with Each Batch

ElastaPro makes fluorosilicone rubber at our Made in USA manufacturing facility in Santa Fe Springs, California. Domestic sourcing can help you to reduce supply chain risk, but that’s not the only reason to buy high-performance materials from us. ElastaPro manufactures fluorosilicone rubber as solid sheets and uncured compound in accordance with our ISO 9001:2015 and AS9100D certified quality management system. Moreover, we offer a full Certificate of Analysis (COA) with each batch.

Why Choose Domestic Fluorosilicone Rubber?

Domestic sourcing reduces your supply chain risk by shortening shipping distances, minimizing transportation touchpoints, and allowing for quicker responses to disruptions such as geopolitical disputes, natural disasters, and pandemics. Along with shorter lead times and greater visibility, the benefits include reduced exposure to international trade issues such as tariffs, border closings, and shipping delays. It’s also easier to coordinate and collaborate with a Made in USA manufacturer.

Even if you can’t visit us in California to meet face-to-face, ElastaPro makes communications easy. Whether you pick up the phone, send us an email, or use the chatbot or contact form on our website, we pride ourselves on quick and responsive service. We’re also available for Teams or Zoom calls and regularly update our website with technical content and descriptions. For example, the fluorosilicone page on our website let you download technical data sheets.

Why Ask for a Fluorosilicone COA?

A Certificate of Analysis (COA) is a document that provides the test results for a specific batch of a material. By contrast, a Certificate of Conformance (COC) simply attests that a material meets requirements. In other words, a COC does not provide batch-level test data. That’s a key distinction in industries like aerospace and defense, both of which use fluorosilicone rubber because of its wide temperature range, superior resistance to fuels and solvents, and ability to meet standards.

ElastaPro provides a full COA with each batch and includes key specifications such as tensile strength, elongation, compression set, hardness, and temperature range testing. Importantly, our COAs demonstrate that our flurosilicone rubber complies with standards such as AMSR-25988, which was published by SAE International and supersedes MIL-DTL-25988. Older prints may still reference MIL-R-25988, which is sometimes written as MILR-25988 instead.

What If There’s a Spec Change or Substitution?

Fluorosilicone specs are subject to change, and suppliers sometimes change the ingredients in their products. That’s why ElastaPro performs a full qualification whenever there’s a spec change or we update a raw material. We also conduct full lot-to-lot verification in accordance with the spec, which contains a table for testing during lot-to-lot qualification work. In the AMSR-25988 specification, Table IV outlines material property requirements.

Ask ElastaPro for Flurosilicone Rubber

Do you need spec-grade fluorosilicone rubber with a full COA for traceability? Have you considered how partnering with a Made in USA materials manufacturer can help you to reduce supply chain uncertainty while ensuring quality? For fluorosilicone solid sheet and uncured compound, the name you can trust is ElastaPro. Contact us for proven materials you can depend upon.

-

Low Durometer Silicone Rubber

Low durometer silicone rubber is a soft, flexible elastomer that offers excellent sealing and cushioning performance in demanding environments. In engineering terms, “durometer” refers to a material’s hardness, typically measured on the Shore A scale for most silicone compounds. Standard silicone rubber is often in the range of 40–70 Shore A, but low durometer grades typically fall between 10–30 Shore A. This softness gives the material unique functional advantages for sealing, vibration control, and conformability.

ElastaPro makes low durometer silicone rubber as solid sheets and uncured compound. Contact us for a quote.

Material Characteristics of Soft Silicones

Low durometer silicone rubber is composed primarily of silicone polymer, reinforcing fillers, and curing agents. Because it’s less densely cross-linked than harder grades, it has a lower resistance to indentation and greater flexibility. It maintains key silicone properties—including thermal stability, UV and ozone resistance, and excellent electrical insulation—while adding the ability to deform easily under pressure. This makes it ideal for applications where a tight seal is required without high compressive forces.

Silicone’s temperature performance is another major benefit. Low durometer grades can typically operate between –60 °C and 200 °C, depending on the formulation. This allows them to remain soft and elastic in both high-temperature engine compartments and low-temperature aerospace or cryogenic applications. Their chemical resistance is also strong against water, weathering, and many common fluids.

Advantages of Low Durometer Silicone Rubber

The softness of low durometer silicone rubber allows it to conform to uneven or irregular mating surfaces. This reduces the need for extremely tight tolerances or surface finishes to achieve an effective seal. For engineers, this means design flexibility: surfaces can be less precise, yet sealing performance remains high.

Another key advantage is reduced compression set stress on mating components. Softer silicone exerts lower clamping force on plastic housings or lightweight structures, helping prevent warping, cracking, or fatigue over time. It can also compensate for tolerance stack-ups or surface imperfections more effectively than harder materials.

Vibration damping is another strength. Low durometer silicone can absorb and dissipate energy, making it useful for reducing vibration and noise in sensitive electronic assemblies or lightweight structures. It’s also often used to protect fragile components from shock.

Common Applications for Low Durometer Silicone Rubber

Engineers often specify low durometer silicone rubber for environmental seals, vibration isolators, and cushioning pads. It is commonly used in enclosures for electronics, including aerospace and defense systems, where soft seals maintain protection against moisture and dust. In medical devices, soft silicone is valued for patient comfort and gentle interface with skin or other sensitive materials.

Automotive engineers use it in gaskets and seals that must accommodate component movement or thermal expansion without leaking. It’s also popular in HVAC and lighting systems where sealing performance must remain reliable despite uneven surfaces or low clamping forces.

When to Use Softer Silicones

Low durometer silicone rubber is ideal when components are delicate, surfaces are irregular, or when maintaining a seal with minimal compression force is required. It’s also advantageous in environments with wide temperature fluctuations or when vibration damping is needed.

However, softer materials may not be appropriate where high mechanical strength or abrasion resistance is required. Engineers should balance softness with durability based on operating conditions.

In short, low durometer silicone rubber provides excellent sealing, flexibility, and environmental resistance—making it a versatile choice for many demanding applications where conformability and low stress are priorities.