FDA silicone rubber provides an optimal balance of safety, performance, and durability for food contact and medical applications. Its compliance with regulatory standards ensures that it does not compromise human health, while its physical and chemical properties support long-term reliability in demanding environments. Whether used in a milk processing plant, a hospital device, or a consumer kitchen appliance, FDA silicone rubber remains a trusted material that helps manufacturers meet both regulatory and engineering challenges. For engineers and product designers, it represents a high-performance, compliant material solution that bridges the gap between innovation and safety.

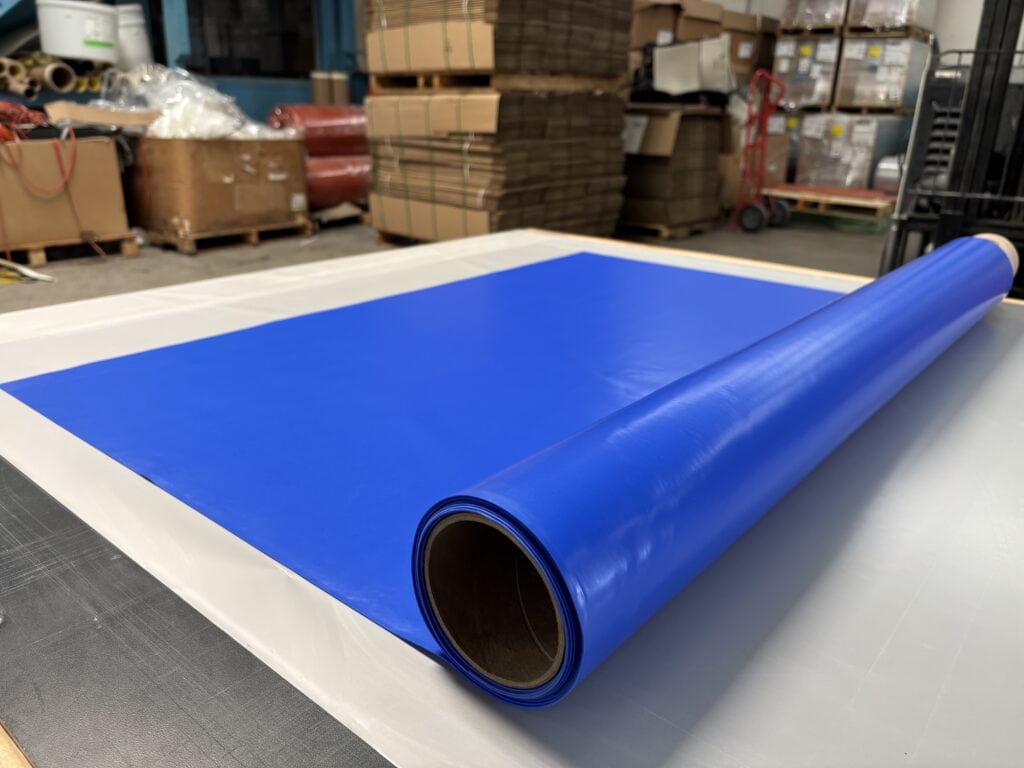

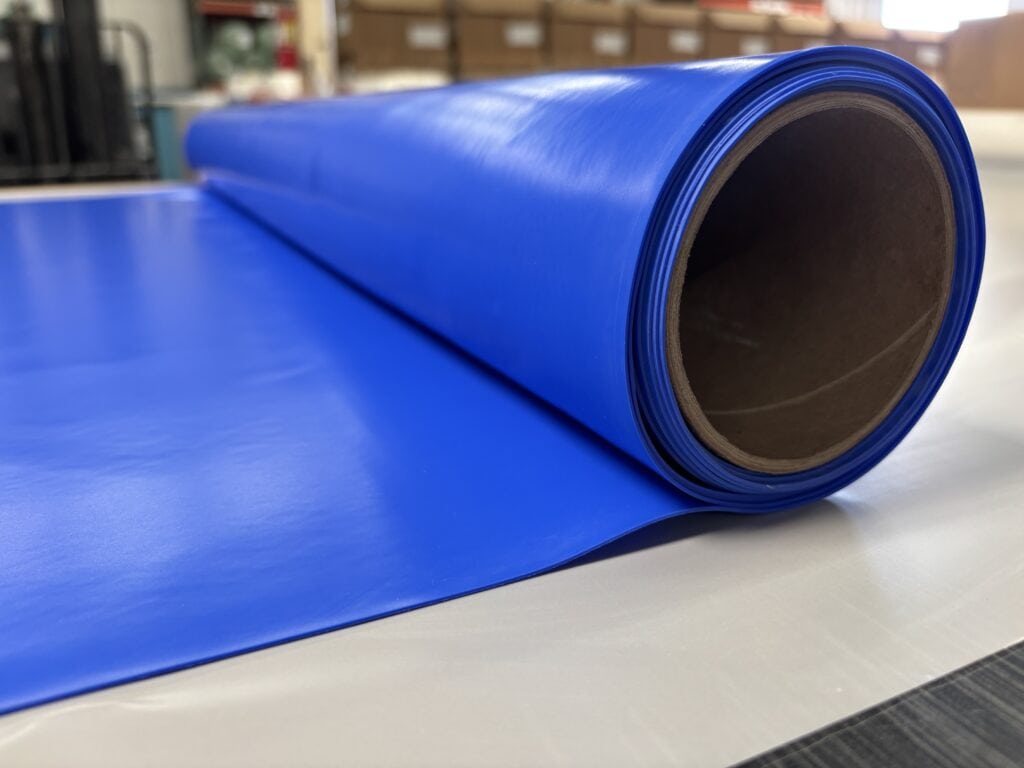

ElastaPro makes FDA silicone rubber in white and translucent, and as solid silicone sheet and uncured silicone compound. We offer low minimum order quantities (MOQs) and our proud to be a Made in USA manufacturer. For a quote, contact us.

What is FDA Silicone Rubber?

FDA silicone rubber refers to silicone compounds formulated and processed to meet the requirements of FDA CFR 21 §177.2600, which governs materials intended for repeated use in contact with food. To qualify, the silicone must not transfer any toxic or unsafe substances to the food or human body under normal use conditions. Typically, FDA silicone rubber is made from high-purity, platinum-cured formulations that are free of additives, plasticizers, or colorants that could pose contamination risks. The material is also odorless, tasteless, and chemically inert—key characteristics for use in regulated industries.

Why Use Silicone?

Silicone rubber is one of the most versatile and reliable elastomers used today, especially in industries that demand safety, cleanliness, and durability. Among its many grades, FDA silicone rubber stands out for its compliance with stringent health and safety standards set by the U.S. Food and Drug Administration (FDA). This compliance makes it ideal for both food contact and medical applications, where materials must perform reliably without leaching harmful substances or degrading under harsh conditions.

Silicone rubber’s unique molecular structure—comprising alternating silicon and oxygen atoms—gives it exceptional thermal stability, flexibility, and resistance to chemicals and aging. It can withstand a wide temperature range, typically from -60°C to +230°C (-76°F to +446°F), without losing elasticity. It resists UV light, ozone, moisture, and microbial growth, making it suitable for both high-temperature sterilization and long-term exposure to demanding environments. Additionally, it maintains its mechanical integrity under compression, shear, and repeated flexing, which are common in seals, gaskets, and tubing.

Food Contact Applications for FDA Silicone Rubber

In the food and beverage industry, FDA silicone rubber is used in products and components that must safely interact with consumables. Common examples include gaskets, seals, tubing, O-rings, and baking molds. Because it remains stable across wide temperature ranges, it performs reliably in both freezing and cooking environments. In processing facilities, it is used in dairy equipment, beverage dispensing systems, coffee machines, and sanitary seals for stainless steel piping. Its non-stick surface properties make it easy to clean and ideal for use in hygienic production lines where contamination control is critical.

Unlike many organic elastomers, silicone rubber does not degrade or impart taste or odor to food products. Its long service life and resistance to cleaning agents reduce maintenance costs and downtime, further enhancing its value in food processing operations.

Medical and Healthcare Applications for FDA Silicone Rubber

In medical and healthcare applications, medical-grade or healthcare-grade FDA silicone is often used in devices that contact the human body or bodily fluids. Examples include catheters, tubing, seals for diagnostic equipment, respiratory masks, and implantable components. Medical-grade silicone typically undergoes even more rigorous testing than food-grade silicone, often complying with USP Class VI and ISO 10993 biocompatibility standards in addition to FDA requirements.

These silicones can be sterilized using steam, ethylene oxide, or gamma radiation without significant property changes. They are also available in various formulations—solid, liquid (LSR), or sponge—allowing engineers to tailor the material to specific design requirements. For example, liquid silicone rubber is often injection molded into complex geometries for disposable medical devices, while solid silicone may be compression molded for reusable components.

For more information, contact ElastaPro.