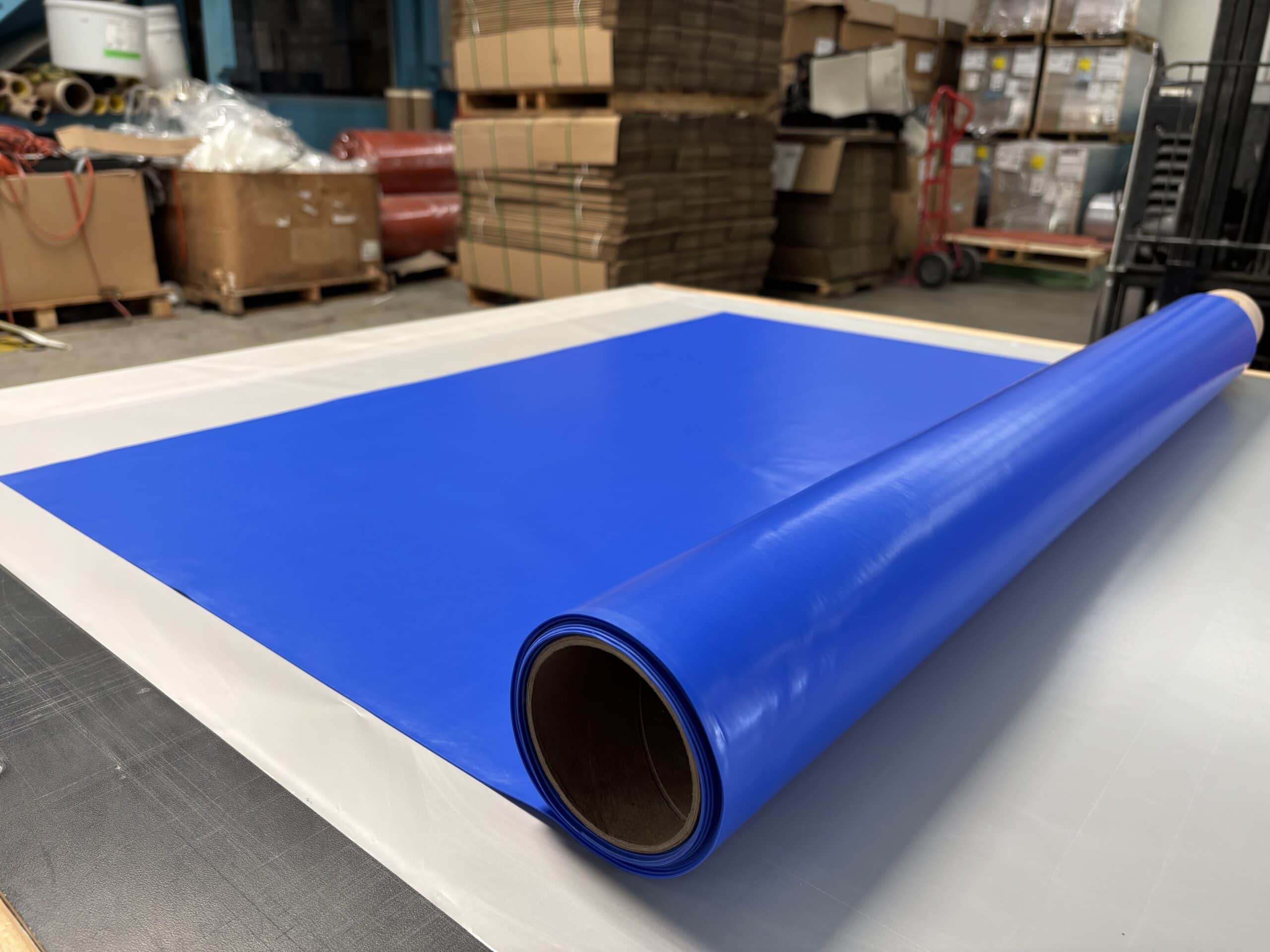

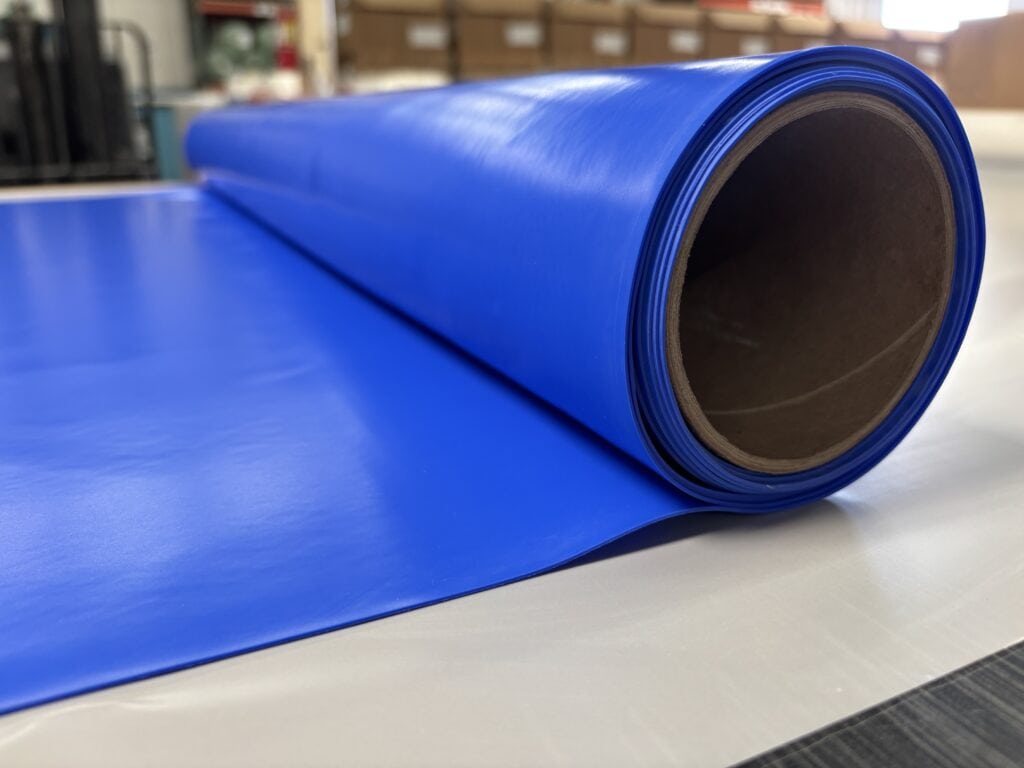

Thin silicone sheet is a high-performance elastomeric material used across industries that demand flexibility, temperature resistance, and durability in compact or precision assemblies. Engineers choose thin silicone sheets when space is limited, sealing tolerances are tight, or lightweight performance is required. These sheets combine the mechanical stability of silicone with the adaptability of thin-gauge materials.

Contact ElastaPro for thin silicone sheet.

Material Properties

Silicone rubber is a synthetic elastomer derived from polysiloxane, a polymer chain featuring alternating silicon and oxygen atoms. This structure gives silicone its unique combination of thermal stability, chemical resistance, and elasticity. Thin silicone sheet retains these base characteristics but in a format designed for precision.

Key properties include:

-

Temperature resistance: Continuous operation from -60°C to +230°C, with some formulations tolerating even higher peaks.

-

Flexibility and resilience: Excellent elongation and compression set performance, allowing for reliable sealing in dynamic or vibrating assemblies.

-

Chemical and UV stability: Resistance to ozone, oxidation, and most environmental agents, ensuring long-term durability.

-

Dielectric strength: Electrical insulation values exceeding 500 V/mil, making it suitable for electronic and EMI/RFI gasket applications.

-

Biocompatibility (optional): Medical and food-grade thin silicones meet FDA, USP Class VI, and ISO 10993 standards for sensitive environments.

Manufacturing and Variants

Thin silicone sheets are produced through calendering, extrusion, or molding processes, depending on the required precision and performance. Calendering yields consistent thickness and smooth surface finish, which is essential for sealing films and membranes. Liquid silicone rubber (LSR) can also be cast into ultra-thin layers with excellent uniformity for optical, electronic, and biomedical uses.

Engineers can select from several material variants:

-

Solid silicone sheet: Offers mechanical strength and dimensional stability.

-

Sponge silicone sheet and foam silicone sheet: Provide compressibility and conformability where surface irregularities must be sealed.

-

Fluorosilicone sheet: Adds resistance to fuels, oils, and solvents for aerospace and automotive environments.

-

Conductive silicone sheet: Filled with metallic or carbon materials for EMI/RFI shielding.

-

Transparent sheet or translucent sheet: Used in lighting, optics, or display applications where clarity is important.

Applications in Engineering Design

Thin silicone sheet is used wherever a durable, flexible, and stable interface is required. Typical applications include:

-

Gaskets and seals: For small enclosures, sensors, and electronics where space and weight savings are critical.

-

Thermal insulation and vibration damping: In electronic assemblies or power systems exposed to heat and mechanical stress.

-

Protective membranes and diaphragms: In fluid control devices, medical pumps, and pressure sensors.

-

Electrical insulation: In high-voltage or sensitive circuitry environments.

-

EMI/RFI shielding layers: When combined with conductive fillers or coatings to prevent electromagnetic interference.

Advantages for Engineers

Thin silicone sheet offers several design advantages. It can be die-cut, laser-cut, or waterjet-cut with tight tolerances, allowing engineers to produce precise gaskets, washers, or films. The material maintains elasticity and performance even at extreme temperatures, reducing maintenance needs. Moreover, thin silicone’s low compression set and long service life contribute to overall system reliability.

From compact electronics to aerospace systems and medical devices, thin silicone sheet represents an ideal combination of performance, precision, and versatility. Its adaptability allows engineers to meet demanding design goals—especially where conventional elastomers fail—making it a cornerstone material in modern high-performance engineering.