High Strength Silicone

High strength silicone from ElastaPro is designed for applications that need greater physical properties than either general purpose silicone or medium strength silicone. High strength solid silicone sheet is easy to fabricate into gaskets and provide a superior sealing solution. These solid silicone sheet materials are available in thicknesses from .010” to .500” and in widths up to 60”. ElastaPro also makes uncured silicone compound.

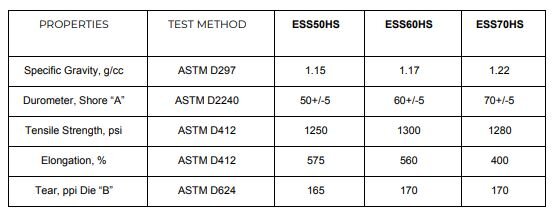

High Strength Silicone Sheet in 50 to 70 Durometer

Choose products in the following durometers.

- ESS50HS- 50 Durometer High Strength Grade

- ESS60HS – 60 Durometer High Strength Grade

- ESS70HS – 70 Durometer High Strength Grade

High Strength Silicone Sheeting: Material Properties Overview

Solid high strength grade silicone sheeting from ElastaPro meets the AA-59588 Class 3B specification (exception to flex).

This table shows properties and test methods for specific products.

High Strength Silicone: An In-Depth Look

Silicones, or polysiloxanes, are a class of synthetic polymers distinguished by their unique silicon–oxygen backbone and organic side groups, most commonly methyl. Within this family, high-strength silicones represent an advanced subset engineered to deliver superior mechanical, thermal, and chemical properties compared to standard silicone elastomers.

Molecular Structure and Crosslinking Mechanisms

High-strength silicone elastomers are based on the repeating siloxane unit (–Si–O–Si–), which provides an unusually flexible backbone compared to carbon–carbon chains in organic elastomers. This bond angle (~143°) and bond length (~1.64 Å) yield high rotational freedom, enabling elastomers with low glass transition temperatures (Tg ≈ –127 °C) and broad thermal operating ranges.

Mechanical reinforcement in high-strength silicone is achieved through:

- Optimized Crosslink Density: Controlled via platinum-catalyzed addition curing, condensation curing, or peroxide curing. High-strength silicones often employ addition curing with functional vinyl and hydride groups to achieve precise crosslink uniformity.

- Filler Reinforcement: Amorphous fumed silica is typically incorporated at 20–40 phr (parts per hundred rubber) to significantly increase tensile strength, tear resistance, and modulus. Surface modification of silica particles with silazane or silanol groups enhances filler–polymer interaction, reducing agglomeration.

- Polymer Molecular Weight Distribution: Narrow molecular weight distributions improve mechanical integrity while reducing creep under load.

These structural enhancements allow high-strength silicones to achieve tensile strengths in the range of 10–14 MPa, which is significantly higher than general-purpose silicone elastomers (4–7 MPa).

Mechanical Properties of High Strength Silicone

Tensile and Tear Strength

High-strength silicones are engineered to withstand elevated stresses. Key values include:

- Tensile Strength: 10–14 MPa (ASTM D412)

- Elongation at Break: 400–700%, depending on crosslink density

- Tear Strength: 30–55 kN/m (ASTM D624), often double that of standard silicones

The tear resistance is particularly critical in gasket and seal applications where mechanical stresses or cut initiation may propagate cracks. Reinforced silicone maintains structural integrity even under cyclic deformation.

Compression Set and Resilience

Compression set (ASTM D395) measures the permanent deformation under load. High-strength silicone elastomers achieve values below 20% at 175 °C/22 hours, outperforming organic elastomers such as EPDM or NBR at comparable temperatures. Low compression set ensures reliable sealing performance in static and dynamic gasket applications.

Resilience, measured by rebound tests, is typically lower than natural rubber but acceptable for damping and sealing applications.

Hardness and Modulus

High-strength silicones are available in a Shore A hardness range of 30–80. Mechanical modulus is tunable through filler content and crosslinking. The material maintains flexibility even at high hardness, a property attributed to the siloxane backbone mobility.

Thermal Properties of High Strength Silicone

The silicon–oxygen backbone provides inherent thermal stability. Key thermal parameters include:

- Glass Transition Temperature (Tg): ~ –127 °C

- Service Temperature Range: –60 °C to +230 °C (continuous), with short-term excursions to 250–300 °C

- Thermal Conductivity: 0.2–0.3 W/m·K for unfilled grades; higher when thermally conductive fillers are incorporated

- Coefficient of Thermal Expansion (CTE): 250–310 µm/m·K, higher than most metals but manageable in compliant sealing applications

At elevated temperatures, mechanical degradation follows a well-defined oxidative mechanism, with chain scission at the siloxane bonds. High-strength silicones are often stabilized with iron oxide or cerium oxide additives to extend thermal endurance.

Chemical Resistance and Permeability

Chemical Resistance

High-strength silicones exhibit strong resistance to:

- Ozone and UV radiation, due to the stability of the Si–O bond.

- Water and aqueous solutions, with negligible hydrolytic degradation at neutral pH.

- Mild acids and bases, though strong alkalis and concentrated acids (e.g., H2SO4, HNO3) cause depolymerization.

- Automotive fluids such as brake fluid, coolants, and transmission oils, with variable resistance depending on formulation.

Swelling in hydrocarbons remains a limitation. Exposure to aromatic hydrocarbons (e.g., toluene, xylene) or fuels (gasoline, kerosene) leads to significant volume expansion. Fluorosilicone variants are preferred in these conditions.

Gas Permeability

Due to its open siloxane structure, silicone has relatively high permeability to gases such as O2, CO2, and N2. For applications requiring barrier properties, engineers employ laminates, coatings, or hybrid material systems.

Electrical and Dielectric Properties of High Strength Silicone

High-strength silicone elastomers retain the electrical insulation characteristics of standard silicones, with:

- Dielectric Strength: ~20–25 kV/mm

- Dielectric Constant (εr): ~2.7–3.2 at 1 MHz

- Dissipation Factor (tan δ): <0.003 at 1 MHz

The material exhibits stable dielectric performance across wide temperature and frequency ranges. High-strength grades are often specified in high-voltage insulation, aerospace connectors, and encapsulation systems where mechanical and electrical robustness are both required.

Processing Considerations

High-strength silicones are manufactured in both high-consistency rubber (HCR) and liquid silicone rubber (LSR) forms.

- HCR (Milling/Extrusion/Molding): Typically used in large-scale parts like hoses, gaskets, and sheets. Requires high-temperature vulcanization (HTV) with peroxide or platinum catalysts.

- LSR (Injection Molding): Two-part, low-viscosity formulations that cure rapidly at elevated temperatures. Precision injection molding enables thin-wall, complex geometries with tight tolerances.

Post-curing is often employed to reduce volatile byproducts, optimize crosslink density, and enhance mechanical properties.

Standards and Testing for High Strength Silicones

Key standards governing high-strength silicone include:

- ASTM D412 – Tensile Properties of Elastomers

- ASTM D624 – Tear Strength

- ASTM D395 – Compression Set

- ASTM D471 – Fluid Resistance

- UL 94 – Flammability Ratings

- ISO 10993 – Biocompatibility for medical-grade silicones

Compliance with these standards ensures reliable performance in aerospace, medical, automotive, and electronics applications.

High Strength Silicone Applications

The unique property profile of high-strength silicone supports demanding engineering uses:

- Aerospace and Defense: Seals, O-rings, and vibration dampers requiring high tear strength and thermal endurance.

- Medical Devices: Catheters, tubing, and implantables where mechanical durability and biocompatibility are critical.

- Automotive: Turbocharger hoses, gaskets, and vibration isolators operating under high heat and pressure.

- Electronics: High-voltage insulation, connector seals, and encapsulants combining dielectric integrity with environmental resistance.

Ask ElastaPro for High Strength Silicones

High-strength silicone represents a class of elastomers engineered to deliver superior tensile, tear, and compression set properties while retaining the intrinsic advantages of the siloxane backbone: broad thermal stability, chemical resilience, and dielectric performance. Through optimized crosslinking, filler reinforcement, and precise formulation, these materials bridge the performance gap between general-purpose silicones and specialized elastomers, enabling their deployment in critical engineering systems across aerospace, medical, automotive, and electronics sectors. For engineers, the selection and specification of high-strength silicone must be informed by the balance between mechanical robustness, environmental resistance, and processing requirements relative to the application’s performance envelope.

For high strength silicones, contact ElastaPro.