Metal Detectable Silicone

Metal detectable silicone is formulated with special additives that makes it detectable by X-ray machines, magnetic separators, or metal detectors. If a piece of a silicone seal or gasket breaks off during production, it can be identified and removed. Applications include food and beverage processing, dairy, and pharmaceuticals. Choose solid silicone sheet or uncured silicone compound.

Metal detectable seals are used to increase safety and reduce downtime by quickly sequestering seal fragments in-process by magnetically collecting the fragments. This material is easily die-cut and provides a superior gasket and sealing solution. Thicknesses range from .010” to .500”, widths are available to 60”, and this material is available in various opaque colors.

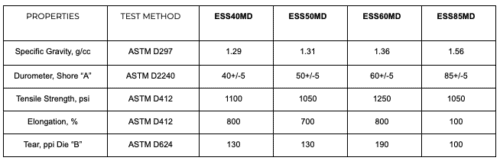

Metal Detectable Silicone in 40 to 85 Durometer

Metal detectable silicone solid sheet comes in the following durometers.

- ESS40MD – 40 Durometer Metal Detectable Grade

- ESS50MD – 50 Durometer Metal Detectable Grade

- ESS60MD – 60 Durometer Metal Detectable Grade

- ESS60MD – 85 Durometer Metal Detectable Grade

Key Characteristics

- Extreme High & Low-Temperature Resistant -85ºF to +525ºF (Intermittent)

- Excellent for Seals & Gaskets

- Fabricated with high-quality and certified raw materials

- UV / Ozone Resistant

- Cured Silicone Sheet is Non-Toxic & Chemically Inert

- Peroxide Free, odorless, and tasteless

- FDA compliant per FDA TITLE 21 CFR 177.2600

- Magnet Pull Test utilizing 20.5 diameter magnet with maximum pull of 4 kg

Material Properties

What are Metal Detectable Silicones?

Metal Detectable Silicone Advantages

-

Detectable by Metal Detectors: If a piece of the silicone breaks off into the product stream, it can be quickly identified by standard detection systems, preventing contaminated batches.

-

FDA and/or USP Compliance: Many grades are compliant with FDA 21 CFR 177.2600 or USP Class VI, making them safe for use in direct food or pharmaceutical contact.

-

Color-Coded: Typically blue for high visibility, as blue is a rare color in food products and easily spotted by workers and optical sensors.

-

Retains Silicone Benefits:

-

Flexible across wide temperature ranges (often -60°F to +450°F)

-

Chemically inert

-

Non-toxic and odorless

-

Resistant to water, steam, cleaning agents, and aging

-

Metal Detectable Silicone Applications

-

Food processing equipment gaskets, seals, and O-rings

-

Pharmaceutical manufacturing tubing and seals

-

Dairy and beverage bottling lines

-

Bakery ovens and conveyor systems

-

Meat and poultry processing plants

-

Preventative maintenance programs to meet HACCP and GMP standards

Additional Considerations

In regulated industries, foreign object contamination is a major safety concern. Metal detectable silicones help:

-

Minimize product recalls

-

Protect consumer health

-

Ensure regulatory compliance

-

Reduce downtime and cleaning costs

For metal detectable silicone, contact ElastaPro.