High strength extreme low temperature silicone is a specialized silicone rubber formulation engineered to maintain excellent mechanical properties (like tear and tensile strength) even at extremely low temperatures, typically as low as -100°F (-73°C) or colder. It combines durability, elasticity, and chemical resistance with the ability to remain flexible and resilient in frigid environments.

Advantages

-

Extreme Low Temperature Flexibility: Unlike standard silicones that may become brittle in sub-zero temperatures, these grades remain soft, pliable, and functional.

-

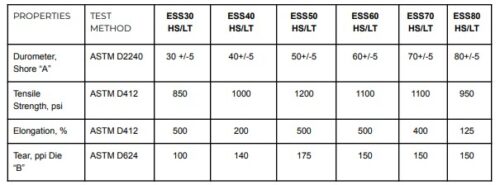

High Strength: Enhanced tensile strength (often >1000 psi), tear resistance, and elongation make it ideal for mechanically demanding applications.

-

Wide Temperature Range: Typically functions from -100°F to +450°F (-73°C to +232°C), with some formulations extending even wider.

-

Resilience: Excellent rebound and compression set resistance even after prolonged cold exposure.

-

Weather and UV Resistance: Performs well outdoors in arctic or aerospace conditions.

-

Chemical Resistance: Resists many oils, solvents, and fuels.

Applications

-

Aerospace seals and gaskets for aircraft exposed to high altitudes and extreme climates.

-

Cryogenic equipment seals (e.g., for LNG or space applications).

-

Military-grade enclosures, boots, and covers.

-

Arctic or deep-sea exploration equipment.

-

Cold storage/freezer door gaskets.

High strength extreme low temperature silicone excels where conventional elastomers would fail due to brittleness or cracking in the cold — while also delivering superior mechanical performance.